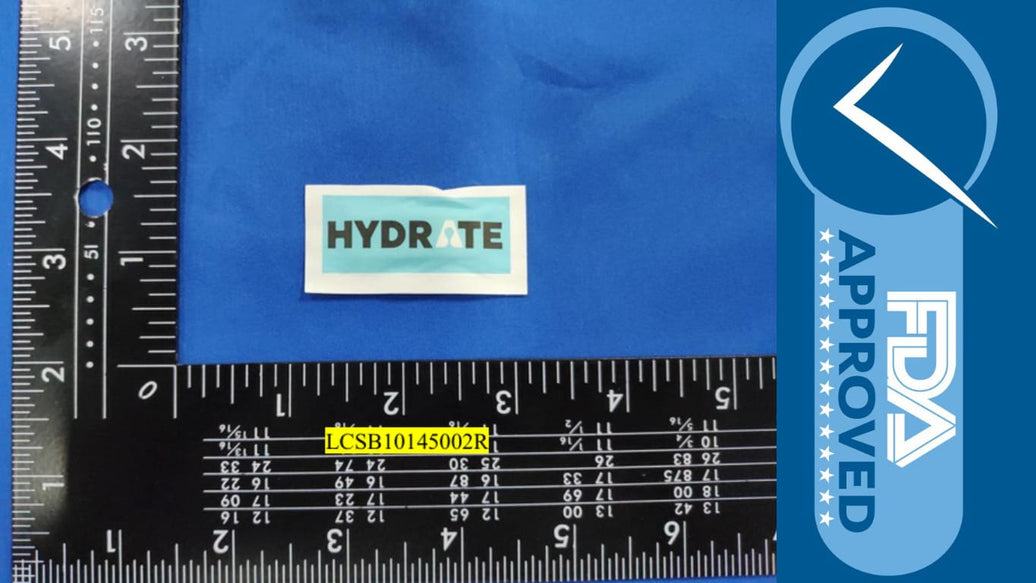

ATMOSIScience announces that the Fiber Humidity Liner, a state-of-the-art moisture barrier solution engineered by Shanghai HengyuanMacromolecular Materials Co., Ltd., has earned dual regulatory certifications from the U.S. FDA: 21 CFR 176.170 for food contact materials safety, and CPG 7117.05 for heavy metals safety compliance. This coveted dual approval exemplifies ATMOSIScience’s expert material engineering and product safety leadership.

Unpacking Dual FDA Regulatory Compliance

21 CFR 176.170

This code ensures paper-based packaging materials used in aqueous, fatty, and alcoholic food contact applications limit harmful substance migration, verified by chemical extraction analysis.

CPG 7117.05

The Compliance Policy Guide focuses on ensuring food-contact materials like paper and aluminum coatings are free of dangerous impurities such as lead (Pb). It guides acceptable limits to ensure no toxic exposure.

Achieving compliance to both standards requires precise chemical composition management and advanced testing protocols encompassing extractable substances and trace heavy metals: a recognition of outstanding product safety.

Comprehensive Testing Outcomes from Shenzhen Southern LCS

Testing under varied extraction conditions demonstrated excellent compliance:

|

Parameter |

Condition |

FDA Limit |

Result |

Compliance Margin |

|

Water Extractives |

Water, 150°F, 2 hrs |

0.5 mg/in² |

0.19 mg/in² |

62% below limit |

|

n-Heptane Extractives |

n-Heptane, 100°F, 0.5 hrs |

0.5 mg/in² |

0.15 mg/in² |

70% below limit |

|

8% Alcohol Extractives |

8% Alcohol, 150°F, 2 hrs |

0.5 mg/in² |

0.23 mg/in² |

54% below limit |

|

50% Alcohol Extractives |

50% Alcohol, 150°F, 2 hrs |

0.5 mg/in² |

0.29 mg/in² |

42% below limit |

|

Lead (Pb) Concentration |

4% Acetic Acid, 24 hrs |

7 mg/L (max) |

Below Detectable Levels |

Total compliance |

Notably, lead testing employed ICP-OES methods ensuring sensitive and precise detection.

Material Innovation for Performance & Safety

The Fiber Humidity Liner combines a durable white paper substrate with an advanced aluminum alloy coating, delivering superior moisture and oxygen barrier properties while maintaining lightness and flexibility. This hybrid design protects high-value pharmaceuticals, foods, and electronics against moisture damage while eliminating heavy metal contamination risk often associated with metalized packaging.

Key Industrial and Commercial Applications

- Pharmaceutical packaging requiring zero contamination risk and moisture control

- Specialty and premium food products demanding fresh preservation and regulatory compliance

- Electronics and precision instruments vulnerable to corrosion from humidity

- Medical devices requiring sterile, heavy metal-free packaging solutions

Commitment to Sustainability and Environmental Health

ATMOSIScience’s Fiber Humidity Liner is validated with internationally recognized certifications evidencing environmental responsibility, such as:

- ISO 14067 Carbon Footprint standard compliance

- EN 13432 Industrial compostability for end-of-life sustainability

These prove ATMOSIScience's dedication to ecological stewardship alongside performance.

Quality Assurance — Delivering Consistency and Trust

Every batch of Fiber Humidity Liner undergoes strict in-house and independent testing, ensuring batch-to-batch compliance and mitigating supply chain risk. The partnership with Shenzhen Southern LCS and other labs embodies transparency and scientific rigor.

Why ATMOSIScience Fiber Humidity Liner Is the Superior Solution

Achieves dual FDA certifications for comprehensive regulatory compliance

- Delivers unmatched moisture and contaminant barrier properties

- Proven non-detectable lead levels remove toxicological concerns

- Robust design balances protection, flexibility, and sustainability

- Serves critical applications where safety cannot be compromised

Conclusion

ATMOSIScience’s Fiber Humidity Liner combines industry-leading safety certifications, cutting-edge material science, environmental consciousness, and proven application versatility in a single premium packaging product. It ensures customers receive trustworthy, high-performance moisture control solutions enabling compliance and product integrity.