Moisture failures in electronics packaging almost never happen because “someone forgot to add a desiccant pouch.”

They happen because moisture control is a system, not a product.

If you want predictable outcomes, you need five things to work together:

-

the right moisture-absorbing mechanism

-

the right bag and pouch materials

-

a standards-based dosage method (UNITS, not guessing)

-

disciplined packing exposure control

-

quality control that protects performance before it ships

This is exactly how ATMOSIScience thinks about desiccant for electronics. Let’s go step by step.

1) First principle: choose by mechanism, not by habit

Start with one question:

What is the moisture-absorbing mechanism of the desiccant?

In packaging, desiccants typically fall into three mechanism categories:

A) Physical adsorption

Examples include silica gel and clay. These materials attract and hold water molecules on their surface.

B) Deliquescence or chemical absorption

Examples include CaO and CaCl2. These materials react or dissolve as they absorb water, which can introduce leakage risk and handling concerns in electronics environments.

C) Hydrogen bonding

Example includes SAP. These rely on chemical functional groups that bind water strongly.

Why mechanism matters: electronics packaging is not only about “how much water can be absorbed.” It is about dust, corrosiveness, stability, and consistency inside a sealed moisture barrier system.

2) Electronics packaging is standards-driven for a reason

In electronics, desiccant selection and calculation commonly anchor to two standards:

-

MIL-D-3464E

-

JEDEC J-STD-033B.1

These standards force the conversation to become specific:

-

What is the absorption definition at a given condition?

-

How do you calculate UNITS based on bag area and WVTR?

-

What handling rules keep the system valid?

This is where many teams realize the problem is not “desiccant quality.” It is that packaging decisions were made without a full system view.

3) The selection framework we use: raw material plus bag material

In electronics packaging, you should evaluate the desiccant system using two sets of properties.

Raw material properties

-

Moisture absorption

-

pH value

-

Corrosiveness

-

Low cost

-

Green

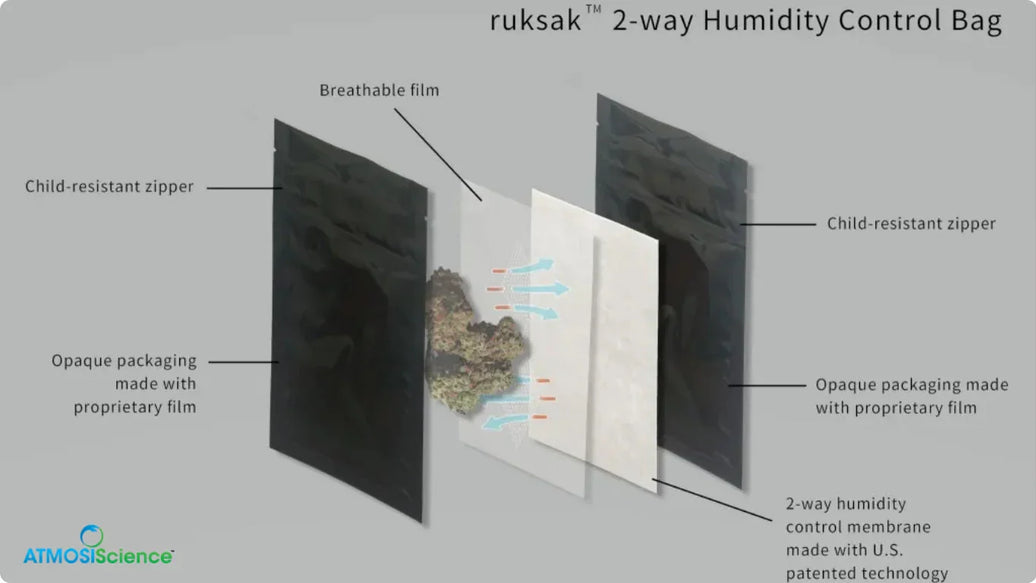

Bag material properties

-

Air permeability

-

Dustproof

-

Bag durability

-

Low cost

-

Green

This split matters because moisture protection can fail even with a strong desiccant if the bag or pouch compromises the system.

4) What “acceptable” looks like in real electronics requirements

A common requirement set used in electronics packaging is clear about what it will and will not allow:

-

The desiccant material shall meet MIL-D-3464, TYPE II

-

Desiccant shall be dustless, noncorrosive, and absorbent amounts specified in the standard

-

The desiccant shall be packaged in moisture permeable bags or pouches

Within this framework, a typical material acceptance list looks like this:

-

Silica gel: Y

-

Clay: Y

-

Molecular sieve: Y

-

Fiber: Y

-

Chemicals: N

This is not saying chemical desiccants never absorb moisture. It is saying that for many electronics packaging programs, the compliance and risk profile push toward dustless, noncorrosive, bagged solutions.

5) The part most teams miss: “Desiccant UNITS” and why they matter

In electronics, desiccant is not counted as “a pouch or two.” It is counted as UNITS.

Desiccant Unit is defined with reference to MIL-D-3464E.

Why this matters:

-

UNITS standardize desiccant usage across different pack sizes.

-

UNITS tie dosage to a defined absorption condition, instead of marketing claims.

-

UNITS make shelf-life planning and MBB design calculable.

Once you move to UNITS, moisture control becomes engineering again.

6) Introducing ATMOSIScience Fiber Desiccant

ATMOSIScience Fiber Desiccant is a patented product designed to meet the electronics reality: high performance, low contamination risk, and controlled usability in packaging operations.

Raw material composition

-

Plant fiber: wooden pulp and cotton

-

Polymer with functional groups such as –Cl, –OH, –NH2

This matters because the fiber structure gives you a stable format, and the polymer functional groups support moisture interaction through bonding.

And it’s not limited to one industry. Our fiber desiccant is already used across:

-

Electronics, garments, stainless steel cookware, pharmaceuticals, cannabis, food supply, tele towers, instruments

Where fiber sits in “types of desiccant” (and why it’s different)

Most people only compare brand vs brand. We prefer to compare material families, because the behavior is fundamentally different:

-

Silica gel

-

Inorganic salts

-

Minerals (clay desiccant belongs here)

-

Organic polymer (SAP)

-

Compound material (fiber desiccant belongs here)

ATMOSISciene Fiber Desiccant is a compound material, which is why it can deliver high absorption while avoiding common drawbacks of loose granular formats.

7) Why fiber format matters in electronics packaging

The fiber approach solves real operational issues that appear on packaging lines and inside sensitive products.

Here are the exact advantages that define the fiber desiccant value:

-

Paper sheet without granular extrusion

-

No leakage danger

-

Higher absorption capacity

-

Better cost performance

-

Degradable and friendly to environment

Let’s translate that into electronics packaging consequences:

“Paper sheet without granular extrusion”

Granules can migrate, shed dust, and create contamination risk. A sheet format is inherently cleaner and easier to handle.

“No leakage danger”

Leakage is not only messy. It can become a reliability risk if liquids or dissolved salts contact components or packaging materials.

“Higher absorption capacity” and “better cost performance”

In electronics operations, cost performance is rarely unit price alone. It is the cost of consistent compliance and reduced packaging failures.

“Degradable and friendly to environment”

Packaging teams increasingly need performance that also fits sustainability direction, especially for high-volume programs.

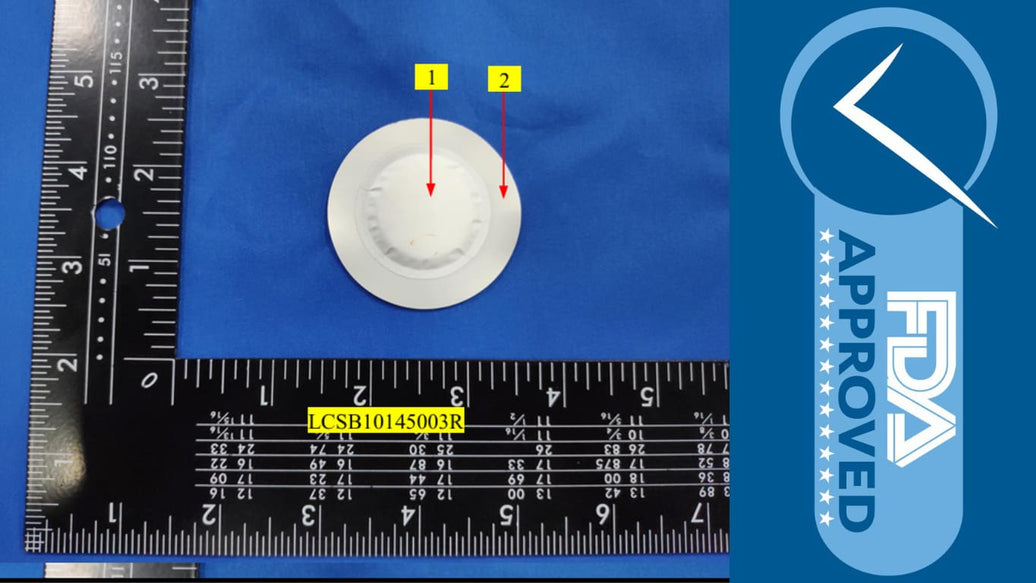

8) Quality control that protects real-world performance

Desiccant performance can be lost long before the customer receives it. That is why quality control is not just lab testing. It is operational discipline.

Key QC controls include:

-

Control water content of raw fiber

-

Control the gram per square meter

-

Test the absorption rate of raw fiber

-

Control the RH in WS

-

Control the exposure time during packing

-

Check the appearance of finished bag

Two controls deserve extra attention in electronics packaging:

A) Control RH in the working space (WS)

If the environment is uncontrolled, fresh desiccant can start loading moisture before it ever reaches the bag.

B) Control exposure time during packing

Exposure time is one of the most underestimated failure drivers.

Which brings us to a simple, strict rule.

9) Practical rules that keep the system valid

Shelf life of desiccant vs shelf life of the electronics product

Is the shelf life of desiccant related to the shelf life of the product?

Not exactly.

Key points:

-

Shelf life: minimum 12 months from bag seal date

-

Active desiccant: fresh (new) or baked to original specs

-

SMD stored in MBB such that a specified interior bag ambient humidity is not exceeded, influenced by WVTR of MBB, desiccant usage, and other factors

How to choose a desiccant

Selection criteria that matter:

-

Moisture absorption rate: the higher, the better

-

Convenient to use: the less usage, the better

-

Safety and security: no potential danger of leakage or extrusion

-

Cost: the lower, the better

-

Green: degradable or friendly to environment

-

Practical:

-

easily judge whether the desiccant is fresh or not

-

simply monitor the interior humidity without opening MBB

-

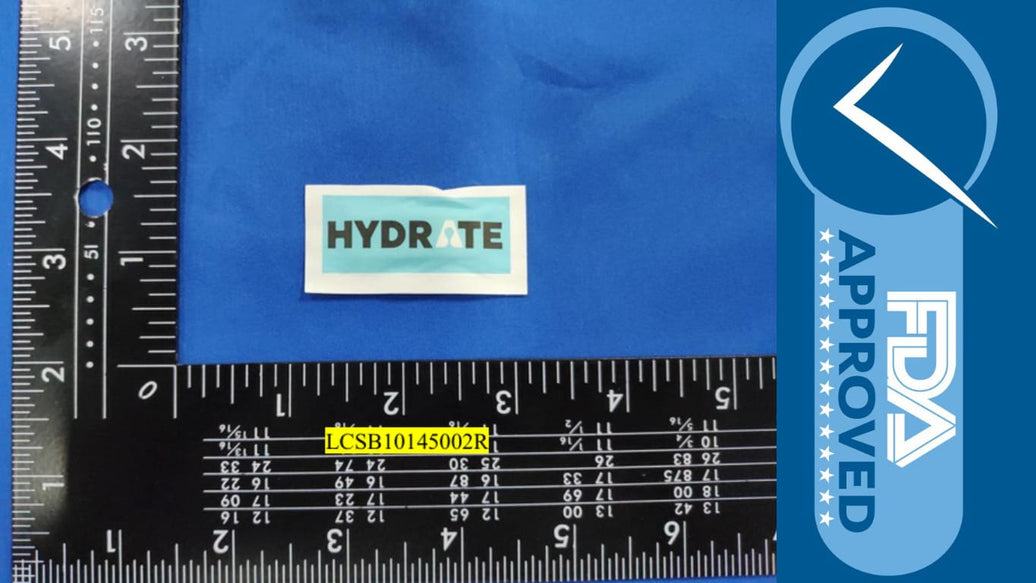

How to know if desiccant is fresh

Use HIC inside the packing.

Maximum exposure time

This is the operational line that many teams should literally print and post near the packing area:

Depends on environmental humidity. If RH < 60%, exposure should be less than 0.5 hour.

That is how you keep performance predictable.

The takeaway: moisture control is engineered, not improvised

A desiccant does not “save” a packaging program by itself.

A moisture-control system does:

-

mechanism selection

-

standards alignment

-

UNITS-based calculation

-

disciplined handling and exposure control

-

quality control that preserves performance through packing

ATMOSIScience Fiber Desiccant fits this system because it was designed for it: sheet form without granular extrusion, no leakage danger, higher absorption capacity, and packaging-friendly bag options that support dustless, noncorrosive requirements.

Let’s chat

If you’re packaging electronics and want to sanity-check your current moisture-control system (mechanism, UNITS dosage, bag materials, and handling discipline), let’s talk.