If you’ve been following the news, you’ve probably seen that Toyota just recalled over 443,000 Tundra and Tundra Hybrid trucks. The issue wasn’t a battery fire or a major mechanical failure — it was something that sounds simple, but cuts deeper than most people realize: moisture got into the reverse lights and caused them to stop working.

That’s it.

Condensation formed inside the lamp housings, corroded the internal electronics, and eventually, the lights failed to turn on when the vehicle was backing up.

It might not sound dramatic — no injuries, no fires — but as anyone in automotive knows, moisture is one of the hardest, most persistent threats to electronic reliability. And this is just one example of how small design oversights can turn into huge recalls when we don’t manage humidity properly.

What Actually Happened?

The root cause was a design flaw in the vent patch used in the Tundra’s reverse light assembly. Over time, the adhesive degraded, the vent seal broke, and moisture slipped in. Once that happens, it's just a matter of time before corrosion begins — especially in a module with tight packaging, electronics, and no way for the moisture to escape.

It’s a classic case of micro-environmental failure: the kind of thing engineers can easily overlook during design reviews, but one that costs millions later in warranty claims, labor, and brand reputation.

Toyota worked with their supplier, Hella, to redesign the lamp with better sealing and issued a free fix — but it begs the question: Why are we still letting moisture win?

This Is Where ATMOSIScience Technology Comes In

We’ve been working on this exact problem for years.

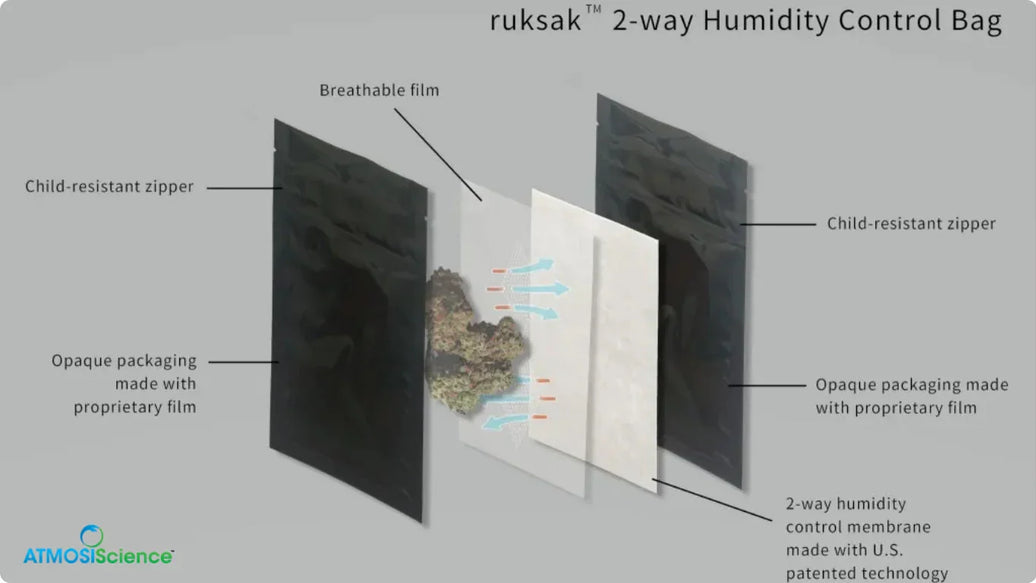

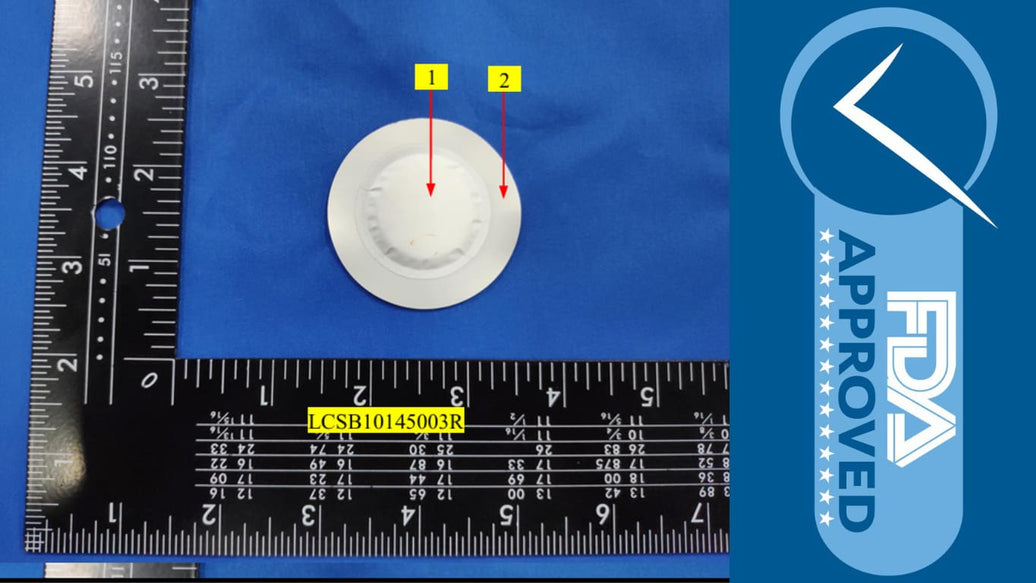

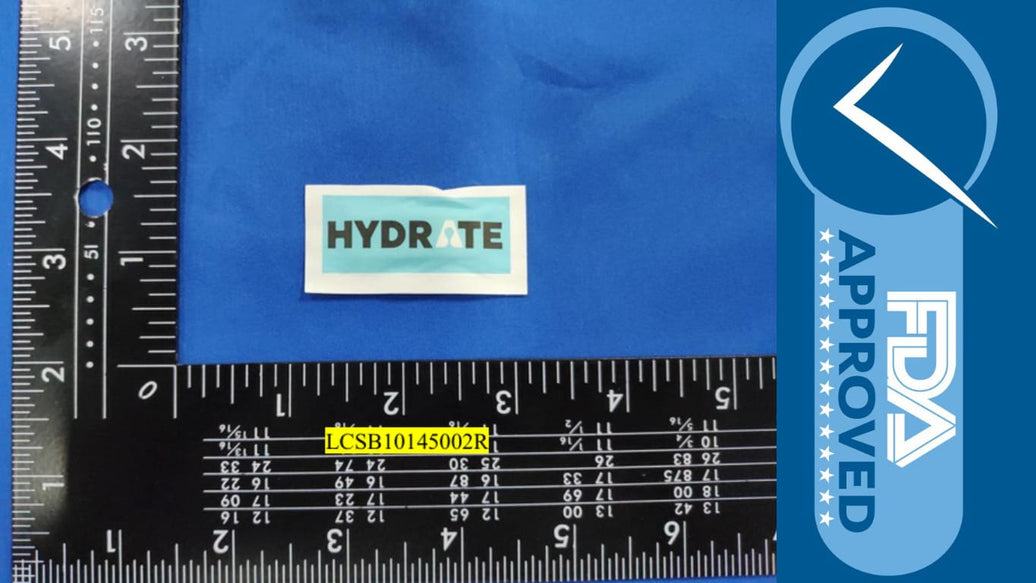

At ATMOSIScience, we make a patented, fiber-based anti-condensation pack that regulates humidity inside sealed systems — not just by absorbing moisture, but by actively balancing the internal microclimate.

It’s built specifically for cases like this:

-

Electronics in a sealed enclosure

-

Exposure to daily temperature swings

-

No room for a fan or power source

-

And no tolerance for corrosion or condensation

Instead of relying on gels, silica beads, or passive vents, our fiber tech does something different. It absorbs or releases moisture based on the surrounding humidity. It keeps the RH inside stable — even when the outside environment isn’t.

And the best part?

It works for over 10 years, requires no power, and fits into a module without any design change. It’s been used in everything from EV battery packs and lighting systems to telecom towers and museum artifacts.

Some Real-World Performance Numbers

We’ve tested our packs under some brutal conditions:

-

At 40°C and 95% RH? They absorb more than 100% of their weight in water within 24 hours.

-

At 40°C and RH between 50–70%? Still over 40% absorption and release capacity.

-

There’s zero seepage, and they’re non-corrosive, even with materials like steel, aluminum, brass, or magnesium.

You stick them inside the enclosure, seal it up, and you’re done. No maintenance. No saltwater. No mess.

Why This Matters for EVs (and Everyone Else)

If you’re building any sort of sealed electronic system — not just reverse lights, but battery enclosures, camera modules, charging ports, domain controllers — you already know this: condensation will find its way in.

The Toyota case just made it visible.

And while we admire Toyota for acting fast and owning the fix, this is a preventable problem. With the right humidity control inside the module, this recall may not have happened at all.

Trusted in Tough Environments

We’ve worked with major names like Samsung and Panasonic. Our packs are used in:

-

EV drive systems and control modules

-

BMS units and tail lights

-

5G towers and base stations

-

Battery energy storage systems

-

Cannabis storage (where terpene preservation is key)

-

Even museums protecting 1,000-year-old scrolls

Because at the end of the day, managing humidity isn’t just about preventing fog. It’s about preserving function — quietly, effectively, and without disrupting design.

Final Thoughts

Toyota’s recall is a reminder: as vehicles get smarter and more electric, the risk isn’t always loud. Sometimes, it’s silent. Moisture doesn’t knock before it enters. It doesn’t throw an error code. It just sits there, slowly breaking down the systems we trust.

If you’re building something that lives in a box — whether it's on four wheels or a pole or a wall — let’s talk.

Because once condensation becomes visible, it’s already too late.

We’d love to help you solve it before it becomes a recall.

Reach out to sales@atmosiscience.com

Or visit atmosiscience.com