Understanding the Cause of Condensation

Condensation occurs when warm, humid air meets a cold surface. This is common in enclosed or poorly ventilated environments, where moisture builds up and eventually condenses into droplets. When the surface temperature drops below the dew point, the water vapor condenses, and in high humidity, this process is accelerated. In small, sealed spaces like electrical enclosures, condensation becomes especially dangerous, damaging electronics and compromising safety.

Limitations of Traditional Anti-Condensation Methods

Many industries rely on physical solutions like vent caps, breather tubes, and waterproof membranes. For example, in car headlights, breathable caps or tubes are often used. However, these solutions are only effective when airflow is present, and they can easily be blocked by dust or dirt. Breather tubes require pressure difference to function properly and are often only effective when the lights are turned on.

Similarly, waterproof membranes are designed primarily for pressure balance and do not actively prevent condensation. In electric control units, compartmentalized cavities are sometimes used to isolate critical areas. But this method doesn’t stop condensation from forming, it only reduces its spread. In many cases, it increases the surface area for condensation to occur.

On the chemical side, anti-fog coatings and desiccants like calcium chloride or magnesium chloride are common. But these materials absorb moisture in only one direction and have a short lifespan, often no more than two years. Once they are saturated, they become ineffective. Worse, many desiccants turn into paste after absorbing moisture and risk leaking corrosive liquids, which can damage nearby electronics.

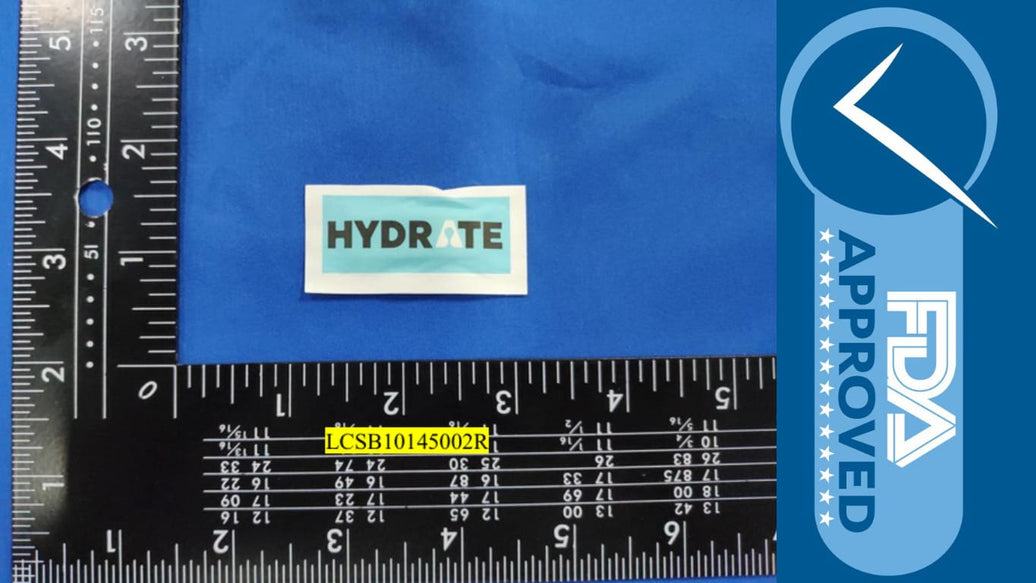

A Better Solution: Anti-Condensation Fiber Pack

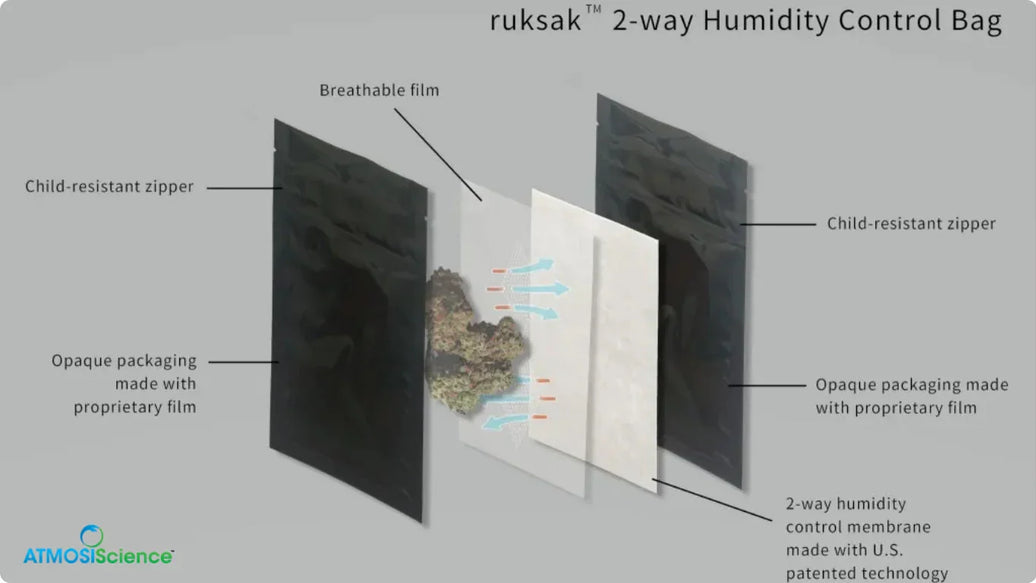

The anti-condensation fiber pack developed by ATMOSIScience offers a more effective solution. Made from a composite material, it uses a two-way humidity regulation mechanism. This means it can absorb or release moisture based on environmental conditions. Unlike traditional one-way desiccants, it helps maintain a balanced humidity level in closed systems, effectively preventing condensation from forming in the first place.

Even after absorbing moisture, the pack remains dry on the outside, without surface damage or leakage. It doesn’t liquefy or produce droplets. The pack dynamically controls the rate of moisture absorption and release, interrupting the formation of condensation before it begins. It protects internal electronics and extends the service life of sensitive components.

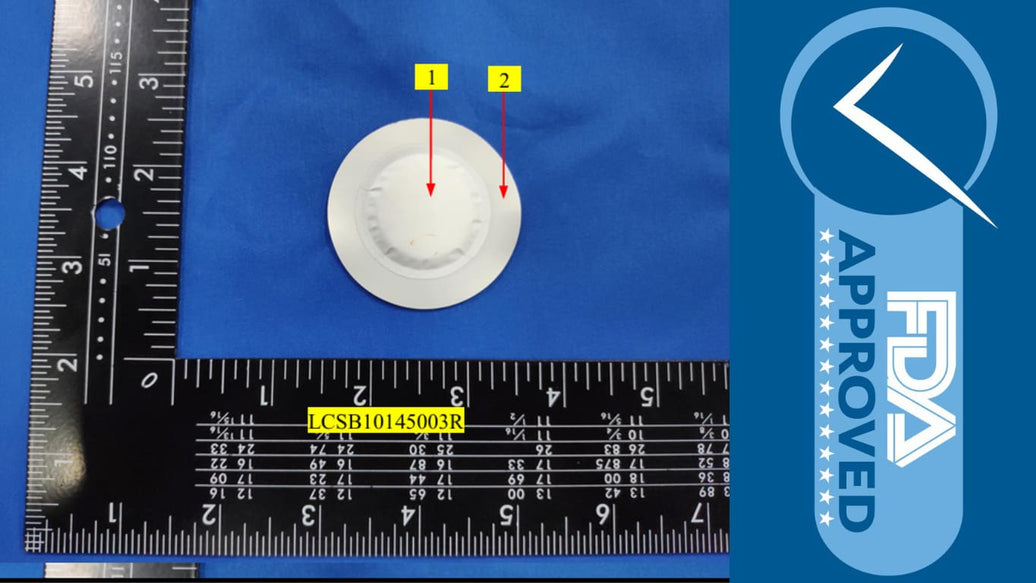

Tests have shown that this anti-condensation fiber pack retains more than 80% of its performance after 10 years of use. It is durable, stable, and designed for long-term applications.

Ideal for Key Applications

This technology is especially suited for micro-environments in electrical systems where temperature varies and airflow is limited. It is now used in electric vehicles (motors, ADAS controllers, headlights), energy storage systems (battery packs, modules, containers), 5G communication base stations (RRU, AAU), and outdoor monitoring equipment, power supplies, and more.

Conclusion

The anti-condensation fiber pack offers a low-cost, safe, and reliable alternative to conventional condensation solutions. It adjusts moisture intelligently and silently, ensuring long-term performance and reducing risks. In high-performance environments where moisture can become a hidden threat, this solution offers peace of mind, one fiber layer at a time.