The final month of 2025 feels different for U.S. cannabis.

Not just because another harvest season is wrapping, but because the entire industry is sitting on a fault line. Federal rules are shifting, hemp-derived THC is entering a new regulatory era, prices continue to slide, and consolidation is reshaping nearly every competitive landscape. Growers everywhere — from legacy operators in the West to craft producers in emerging East Coast markets — are asking the same quiet question:

“What can I still control?”

It’s a fair question in a year when the Supreme Court is weighing whether to reopen the debate on federal prohibition, and when the hemp-derived THC category — once the fastest-moving segment of cannabinoids — is now navigating a federal ban scheduled to take effect next year. Against this backdrop, one truth has become harder to ignore:

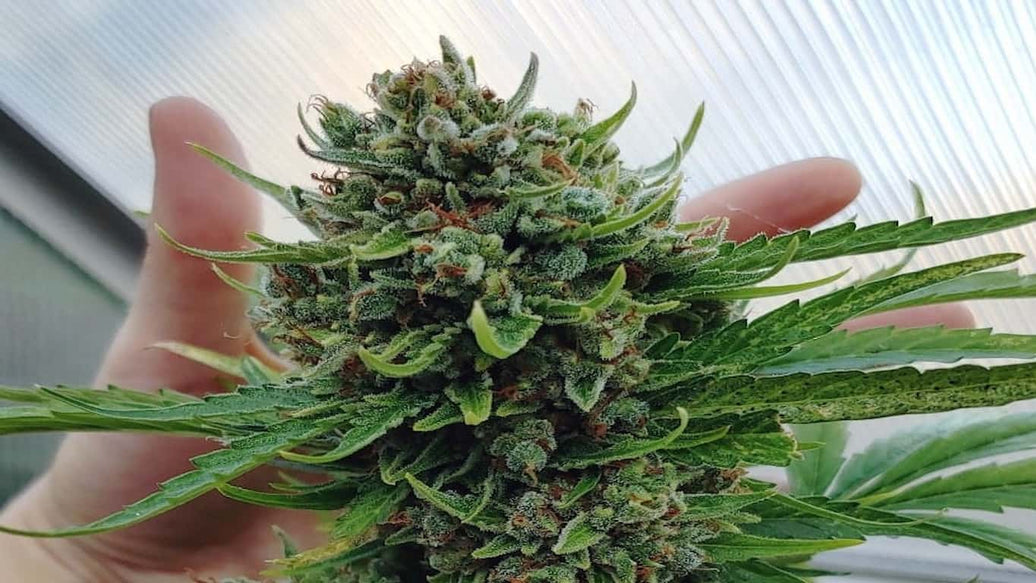

Moisture — the subtlest variable in your facility — now determines the quality, weight, and sellability of your flower more than ever.

And the growers who are staying ahead aren’t waiting for federal clarity.

They’re tightening their post-harvest environments today.

The U.S. Market Is Evolving. Quality Is Becoming the Real Differentiator.

Even with price compression and oversupply, demand for premium flower keeps climbing. National sales are projected to cross $45 billion this year, but that number hides a sharper story: while low-tier volume rises, the only category consistently growing in retail share is top-shelf, terpene-rich product. Consumers are becoming more discerning, and new minor-cannabinoid and effect-driven formulations are pushing brands to compete on nuance, consistency, and sensory quality — not just THC percentage.

That means growers must protect aroma, weight, and cultivar expression from the moment branches are cut all the way through conditioning, final cure, and storage. One bad humidity fluctuation can flatten terpenes, trigger microbial concerns, or cost you percentage points in weight — and in a market fighting for margins, those grams matter.

This is where many U.S. cultivators are re-evaluating old tools and adopting something that feels both simple and surprisingly advanced: fiber-based humidity control.

The Shift from “Managing Humidity” to “Stabilizing Water Activity”

For years, growers relied on mechanical dehumidification and salt-based humidity packs. They worked — mostly. But as the market matured, limitations became obvious: liquid packs could leak or crystallize, RH drifted more often than expected, and consistent results from tote to tote were hard to maintain.

What growers needed wasn’t more HVAC horsepower.

They needed something that stabilized the microclimate inside every jar, tote, and pound bag — where the flower’s fate is actually decided.

ATMOSIScience approached this differently. Instead of using salt solutions or oil-based additives, they engineered a natural fiber substrate made from bamboo and wood pulp. Inside that substrate, hydrophilic polymers interact with moisture through a controlled balance of adsorption and release. In plain language:

The material “breathes” with your flower, holding RH steady within a narrow band — without liquid, without salt, and without swings.

For U.S. growers fighting dryness in Colorado, excess humidity in the East, or inconsistent environmental controls in mixed-climate facilities, this shift has been a quiet breakthrough.

Humidi-Cure®: Precision for the Cure Jar, the Tote

If you walk into any U.S. facility this year, you’ll hear growers talk about the changing expectations of wholesale buyers. A consistent cure — not too dry, not too wet — is the price of entry. This is where Humidi-Cure®, ATMOSIScience’s 62% fiber-based pack, has stepped into the spotlight.

Unlike traditional moisture packs, Humidi-Cure® is entirely liquid-free and salt-free. There’s no brine, no risk of leaks, and no corrosion hazards around metal shelves or sealed packaging. More importantly, its fiber structure gives it exceptionally fast response time. When the flower gives off moisture, the pack absorbs; when the environment dries, it releases — always pushing the microclimate back toward 62% RH with surprising accuracy.

Growers have noticed something else:

Flower conditioned with fiber-tech tends to hold weight better and retain a richer aromatic profile during the weeks when wholesale decisions are made.

If you want a deeper look at how the technology works inside your containers, you can explore Humidi-Cure® here: https://atmosiscience.com/pages/humidi-cure

ruksak®: Inside the 1-Pound Bag, a Different Revolution Is Happening

If Humidi-Cure® sharpened the cure, ruksak® changed the pound bag.

Until recently, growers kept humidity packs and bags separate.

That meant labor, counting, inserting, and managing packs across thousands of pounds — and if someone forgot a pack, that batch was compromised.

ruksak® removes the entire step.

Every bag has the same fiber-tech humidity layer built directly into its inner membrane, regulating moisture around 62% RH for the entire life of the sealed pound. It’s effortless: you fill the bag, seal it, and the bag takes over. No loose packs. No salt. No liquid. No surprises.

For indoor cultivators producing uniform batches, ruksak® has become a quiet competitive advantage. Pounds stay consistent. Weight loss slows. Aroma survives long storage and transport. And because the bag actively manages moisture rather than just “trapping” it, even slightly overdried flower can recover toward a better water-activity band — often enough to make the difference between mid-tier and premium presentation.

Growers curious about the integrated bag system can explore ruksak® here: https://atmosiscience.com/pages/ruksak

Why Fiber-Based Humidity Control Is Becoming a U.S. Standard

2025 has revealed something valuable about the cannabis market:

The brands and cultivators thriving right now aren’t just scaling; they’re becoming meticulous. They treat post-harvest like a scientific process, not a final chore. And they understand that environmental stability — especially humidity — is the invisible thread connecting everything from yield preservation to terpene quality to safety compliance.

What ATMOSIScience offers resonates because it solves a simple but overlooked truth:

Cannabis doesn’t fail in the grow. It fails between the grow and the sale.

Humidity swings cost money.

Inconsistent cure costs buyers.

Lost aroma costs brand loyalty.

And in a year defined by regulatory unknowns, price pressure, and shifting consumer preferences, U.S. growers are doubling down on what they can control — the microclimate around every gram of their harvest.

The Future Is Lean, Precise, and Fiber-Driven

As 2026 approaches, the conversation in cultivation is moving beyond equipment lists and into invisible variables: water activity, terpene volatility, equilibrium RH, packaging microclimates. Precision at tiny scales is becoming the path to resilience in a volatile national market.

That’s why more growers are adopting Humidi-Cure® to stabilize their cure and ruksak® to protect their pounds. The technology doesn’t demand new workflows. It adapts to the way cultivators already operate — but with a higher degree of control and a more predictable outcome.

In a year where so much feels uncertain, the growers who will stay ahead are the ones protecting their flower with the same care they use to grow it.