You've invested months perfecting your grow operation. The lights were dialed in, the nutrients balanced, and the airflow optimized. Now, as the final stretches of harvest season approach, the real challenge begins - protecting everything you've cultivated during those critical weeks after the plants come down. The truth that many growers discover the hard way is simple but sobering: one week of unstable humidity can undo months of perfect cultivation.

This is the pivotal moment where genetics, technique, and precision collide. What happens in your drying and curing environment determines whether your flower maintains its full spectrum of cannabinoids, terpenes, and visual appeal - or whether it slowly degrades into a mediocre product that fails to reflect the work you've invested.

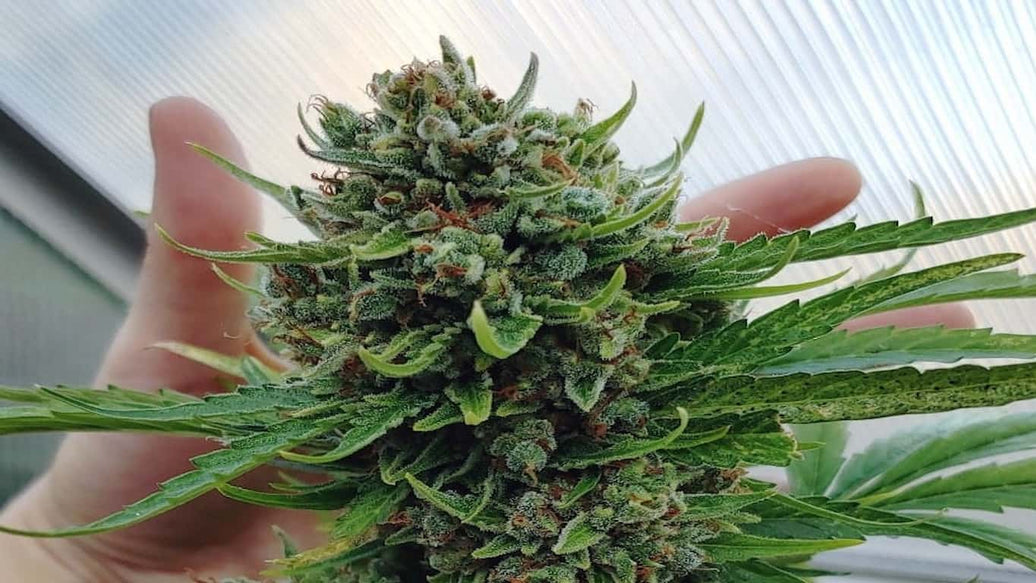

Timing your harvest for maximum potency and terpene content

The harvest window is narrower than many growers realize. The distinction between an exceptional harvest and a merely acceptable one often comes down to timing measured in days - sometimes hours.

Peak terpene and cannabinoid levels occur in the early morning hours, before the plant has responded to light exposure. THC, CBD, and the full spectrum of terpenes reach their highest concentrations during this dawn window. This isn't coincidence - it's cannabis physiology. Throughout the day, as light exposure increases and temperatures rise, plants naturally metabolize and transpire these volatile compounds. Waiting until midday or afternoon to harvest means losing a significant portion of what makes your flower valuable.

For optimal results, harvest between 4 AM and 8 AM, when trichomes are at their most resinous and terpene profiles are at their peak. The cooler morning temperatures also help preserve the delicate trichome structure, which houses the cannabinoids and terpenes you're trying to protect.

For more informations, discover our blog: Morning or Night? Find the Best Time of Day to Harvest Cannabis

When determining exactly when to harvest, examine the trichomes through a magnifying glass or jeweler's loupe. The ideal window appears when approximately 70-90% of trichomes have transitioned from clear to a milky white color, with perhaps 10-20% turning amber. This represents the sweet spot for maximum THC levels combined with a balanced effect profile. If your goal is a more sedative product, you can wait until 30% or more of trichomes show amber coloration. However, once trichomes begin looking grey or withered, your harvest window has passed, and waiting further will only degrade potency and introduce the risk of mold in the flowering environment.

The science of drying: Temperature and humidity are non-negotiable

Once your plants are cut and brought inside, you've entered perhaps the most critical phase of post-harvest quality control. The difference between a quality-preserving dry and a quality-destroying one comes down to precise environmental management.

The ideal drying environment maintains a temperature between 60-70°F with relative humidity between 45-55%. These conditions allow moisture to evaporate at the optimal rate: slowly enough to prevent terpene loss through rapid evaporation, but fast enough to prevent mold colonization.

Explore: Expert Guide on How to Harvest Cannabis and Dry It Properly

What happens at the extremes? If humidity drops below 45%, your buds begin drying too rapidly. The outer layers of the flower lose moisture while the interior remains wet, creating brittle, crispy edges that shed trichomes easily. More critically, rapid drying accelerates terpene evaporation. These volatile aromatic compounds literally escape into the air, and once gone, they cannot be recovered. Your final product loses the nuanced flavor and aroma profile that defines quality cannabis.

Conversely, if humidity climbs above 55%, moisture lingering in the buds creates an ideal environment for mold, mildew, and other pathogens. Botrytis, the most destructive bud rot pathogen, thrives in warm, humid conditions and can destroy significant portions of your harvest within days. Even if mold doesn't take hold immediately, excessive moisture creates conditions for cannabinoid degradation and undesirable chemical reactions that dull your flower's potency.

The drying phase typically takes three to seven days, depending on bud density and environmental conditions. A well-ventilated space is essential - stagnant air allows moisture to accumulate and creates hot spots where mold can establish itself. Aim for gentle air circulation rather than strong airflow, which can stress trichomes and accelerate terpene loss.

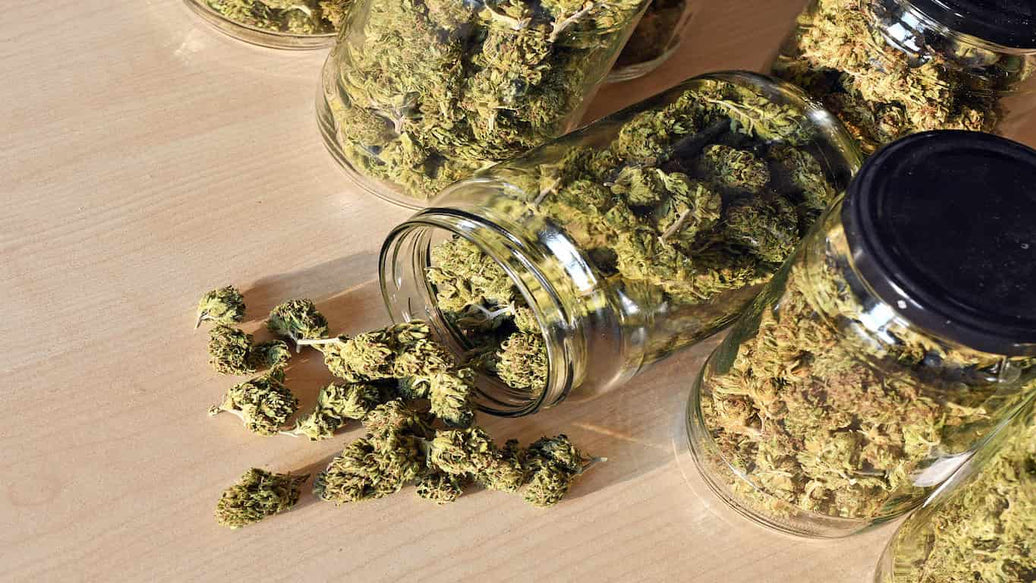

Beyond drying: The curing process that locks in quality

Many growers mistakenly believe their work is done once buds feel dry to the touch. In reality, drying is only the first half of post-harvest quality management. Cannabis curing is where the final cannabinoid and terpene profiles are truly locked in.

During curing, moisture that remains in the interior of the buds gradually migrates outward and evaporates. This process takes additional time - ideally two to four weeks - but it's during curing that several critical chemical transformations occur. Chlorophyll and other harsh-tasting compounds break down, resulting in a smoother, more refined flavor. Remaining moisture is distributed evenly throughout the flower, preventing hot spots of excess moisture that can still support mold growth. Most importantly, the full terpene profile stabilizes and melds with the cannabinoid structure, creating the complete sensory experience consumers expect.

The ideal curing environment should maintain approximately 50-65% relative humidity at temperatures around 65°F in a low-light space. The slight increase in humidity during curing (compared to drying) prevents over-desiccation while maintaining mold prevention. This is why humidity control matters so much - stability within this range is what determines success or failure.

The real risk: Humidity swings and environmental inconsistency

Here's where many operations fail, particularly during the final harvest push when multiple rooms and bulk containers are in various stages of cure simultaneously. Humidity doesn't remain constant across different parts of your facility. One corner of your drying room might hover at 48%, while another creeps to 58%. Bulk bins stacked near external walls experience different humidity than those in the room's center. Individual jars in storage can have dramatically different microenvironments based on their location and seal quality.

These swings - even 5-10% variations - cause stress on trichomes and accelerate terpene volatilization. When humidity fluctuates, water moves in and out of the flower tissue rapidly, creating mechanical stress that ruptures delicate trichome heads. The moment a trichome ruptures, its contents - cannabinoids and terpenes - begin oxidizing and degrading. Once lost, this quality cannot be recovered.

Solutions for the final harvest push

As you enter the final month of harvest season, precision becomes increasingly difficult without the right tools. ATMOSIScience offers leading 2-way humidity control products to keep your harvest stable and flavorful:

- ruksak bamboo bags: Maintain a steady 62% RH for freshly cut buds to prevent rapid drying and terpene loss.

- Humidi-Cure packs: Regulate RH with ±2% precision inside jars and bulk bins for even curing and long-term storage.

- ATMOSISciecne liners: Control microclimates in individual jars and barrels, locking in aroma and smoothness through curing.

The bottom line: Quality is determined after harvest

Your cultivation excellence is only as good as your post-harvest execution. Maintaining tight environmental control during drying and curing preserves terpene profiles, trichome integrity, and visual appeal, consistently producing premium flower quality.

Now is the time to audit your drying and curing environments, measure humidity and temperature variability, and invest in tools like those from ATMOSIScience to protect and unlock the full value of your harvest. Because your months of hard work deserve to reach the market at their peak.