Cannabis processing equipment is the critical foundation of modern cannabis production. The cannabis industry has evolved rapidly, with post-harvest processing becoming vital to delivering high-quality products. During this stage, cannabis loses approximately 75% of its weight through moisture removal, making the proper processing equipment essential for preserving potency and safety.

Effective cannabis processing must meet rigorous GMP standards and regional regulations, especially for volatile extraction processes. Advanced cannabis equipment technology reduces labor costs by over 50%, increases operational efficiency, and guarantees consistent batch quality. This blog explores essential cannabis processing equipment, production techniques, and how to maintain product quality throughout processing and storage.

Post-harvest drying and curing equipment: Maximizing cannabinoid preservation

The global drying and curing cannabis equipment market is booming, valued at USD 196.4 million in 2024 and projected to grow at a 9.5% CAGR to USD 339.2 million by 2030. This growth reflects widespread recognition that drying methods drastically affect product quality and shelf life.

Explore more our blog: Expert Guide on How to Harvest Cannabis and Dry It Properly

Traditional hang-drying can take 7-14 days and often leads to inconsistent results with cannabinoid degradation. Modern methods such as controlled atmosphere drying (CAD) accelerate drying by 60% while retaining volatile terpenes. Maintaining temperature control between 60-70°F (15-21°C) is crucial to prevent cannabinoid breakdown; temperatures above 105°C can convert THC into less potent CBN.

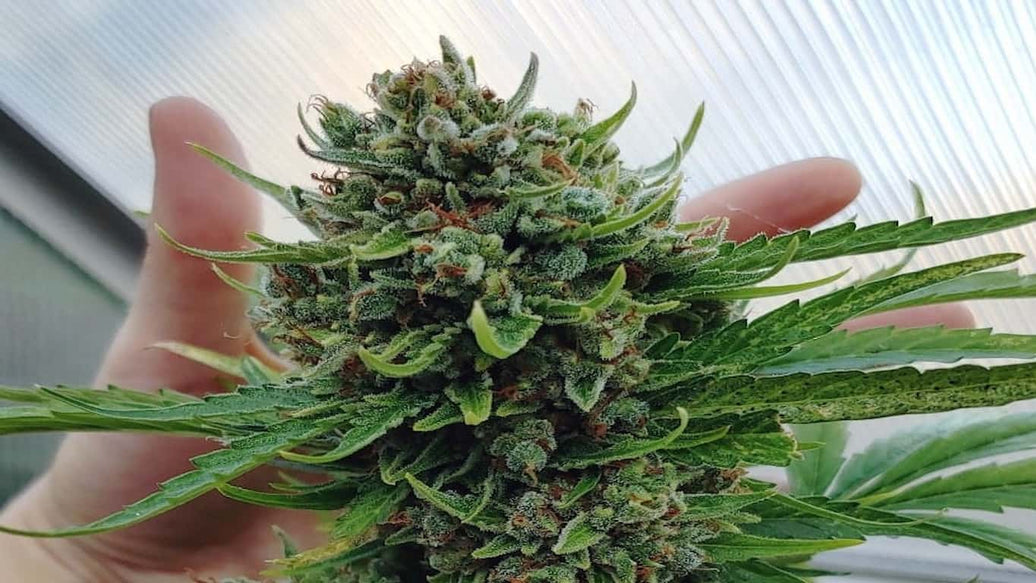

Humidity control during cannabis curing must stay between 55-60% relative humidity to prevent mold and preserve trichomes. Advanced freeze-drying technology reduces drying time to 10-15 hours, preserving key aromatic compounds, although it requires significant energy input. Innovative REV (Radiant Energy Vacuum) systems combine microwave heating and vacuum to retain terpene profiles while speeding up drying cycles.

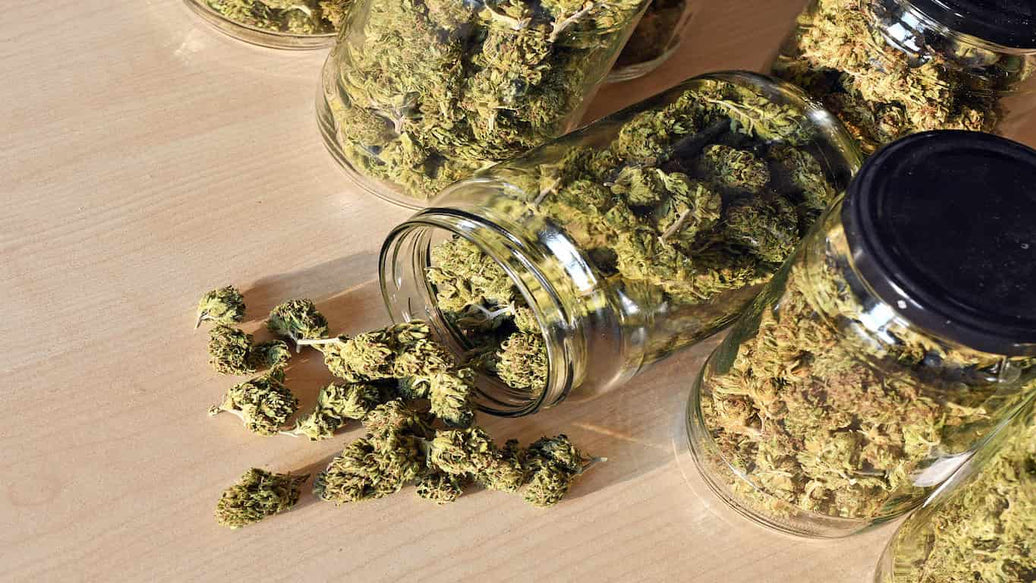

Precision water activity measurement tools ensure dryness without overdrying. After drying, using proper storage containers is essential. Options include glass jars with airtight seals, vacuum-sealed bags, and Mylar packaging with aluminum foil, all designed to eliminate oxygen exposure and block light degradation. Complement these with humidity packs (58-62% RH) to maintain optimal moisture for freshness.

For comprehensive storage solutions, consider ATMOSIScience’s patented ruksak humidity control bags, which maintain precise humidity levels for up to 12 months, preserving freshness and potency effectively.

Trimming and processing equipment: Optimizing harvest quality

Trimming cannabis represents the final touch before extraction or sale. Manual trimming preserves 80% of flower quality but is time-intensive (~3-4 hours/lb). Automated cannabis trimming equipment drastically reduces labor costs and increases throughput, processing over 400 pounds daily per operator.

Utilizing precision trimming tools - including ergonomic pruning shears with non-stick coatings and high-quality trimming scissors - helps maintain trichome integrity. Magnifying loupes support optimal harvest timing by enabling detailed trichome observation.

Enhance yield value by integrating kief collection systems during trimming. Three-chamber grinders and multi-stage silk-screen filters capture potent dry sift (kief) used to produce concentrates like hash, rosin, and moonrocks. Commercial tumbler systems further increase recovered cannabinoid concentrations, with kief potency reaching 35-50% THC.

For detailed accessory options and best practices, explore ATMOSIScience’s blog on Cannabis Dispensary Supplies: Essential Medical Accessories.

Extraction equipment and Methods: Achieving target cannabinoid profiles

The cannabis extraction equipment market is expanding rapidly, driven by high demand for concentrates and oils. Here are the primary extraction technologies:

Solvent-based extraction systems

CO₂ supercritical extraction uses pressurized carbon dioxide at 31°C and 1,071+ PSI to selectively extract cannabinoids. This closed-loop extraction equipment costs between $50,000 and $200,000+, producing clean, tunable full-spectrum extracts with 40-90% THC concentration.

Ethanol extraction employs cold ethanol in centrifuge extractors (−40°C) and rotary evaporators for solvent recovery reaching 99%. This food-safe method suits edibles production and commercial throughput up to 400 lbs/day.

Hydrocarbon extraction (BHO) uses butane or propane in explosion-proof, UL2208 certified systems to make concentrates like shatter and live resin. Throughput is typically up to 18 lbs/hr with potency between 70-90% THC. Luna Technologies is a top manufacturer of automated BHO extractors.

Solventless extraction technologies

Rosin press technology applies hydraulic or mechanical heat (180-220°F) to extract pure concentrates from hash or flower without solvents. Lowtemp Industries offers industry-leading rosin presses that preserve terpenes and produce solventless extracts quickly.

Ice water extraction (bubble hash) uses freezing and micron-sized filter bags to separate resin glands. This process retains 31% more terpenes than dry sift and yields extracts over 50% THC potency from fresh-frozen material.

Quality control and testing equipment: Meeting regulatory standards

Robust cannabis potency testing is essential. Industry-standard HPLC instruments quantify THC, CBD, CBN, and acidic precursors in under 20 minutes. LC-MS/MS and GC-MS provide sensitive terpene and contaminant profiling.

Microbial safety is verified via culture-based tests and rapid PCR analysis. Heavy metals and residual solvents are monitored using ICP-MS and GC-FID, ensuring product safety and regulatory compliance.

See ATMOSIScience’s resources on cannabinoid profiling and testing at "How To Store Your Weed (Best & Worst Methods)" for best laboratory practices.

Equipment for edibles and tinctures: Production and packaging innovation

Decarboxylation systems heat cannabis at 220-240°F to activate cannabinoids. Closed-loop vacuum ovens minimize terpene loss, with commercial units costing $15,000-$40,000.

Automated infusion equipment blends cannabinoids precisely into oils and butters at optimal temperatures. Vape cartridge filling machines such as the VERSA5 Cartridge Filler deliver high-throughput, bubble-free filling at controlled temperatures (50-200°F).

The cannabis packaging equipment market is surging, with automated solutions handling weighing, sealing, and labeling to meet child-resistant and regulatory standards. Vacuum sealing and humidity control packaging like ATMOSIScience’s Humidi-Cure® packs optimize product freshness.

Contamination control and regulatory compliance: Facility standards

Strict GMP facility requirements mandate stainless steel, non-porous surfaces and clean-room environments. Personnel follow scrubs, masks, and frequent glove changes protocols. Segmented equipment prevents cross-contamination, with validated cleaning using vaporized hydrogen peroxide systems.

Compliance varies by state but demands seed-to-sale traceability and third-party audits. ATMOSIScience’s blog "The Way You’re Storing Weed Might Be Causing Mold" offers storage safety advice crucial to contamination control.

Optimization strategies: Maximizing yield and quality

For terpene preservation, use fresh-frozen starting material, low-temperature drying, and solventless extraction, retaining up to 60% more aromatics. Cannabinoid retention is supported by light-excluding storage and oxygen reduction through vacuum sealing.

Automation cuts labor costs dramatically, while solvent recovery saves over $50,000 annually in operational costs.

For more on humidity mastery from seedling to storage, visit ATMOSIScience’s Best Humidity for Cannabis: Mastering from Seedlings to Storage.

Conclusion

Investing in the right cannabis processing equipment optimizes quality, compliance, and profitability. Staying ahead means adopting advanced extraction methods, precise drying technologies, stringent contamination controls, and leveraging automation.

With informed equipment selection and optimized processing workflows complemented by storage innovations like ATMOSIScience’s patented ruksak humidity control bags, producers can consistently deliver premium cannabis products that meet consumer expectations and regulatory requirements.