Harvesting plays a pivotal role in determining the final quality, potency, and market value of cannabis. Whether managing a small-scale grow or a commercial operation, selecting the ideal cannabis harvesting tools and cannabis harvesting equipment can dramatically influence both short-term labor costs and long-term crop consistency. This comprehensive guide breaks down the most effective manual and mechanical gear, details best practices for timing and postharvest handling, and links to AtmosisScience’s premium storage solutions - ensuring every bud retains its peak aroma, flavor, and cannabinoid profile.

Understanding harvest timing and preparation

Accurate harvest timing is the cornerstone of any successful cannabis operation. Overripe or underripe flowers can compromise potency, flavor, and yield.

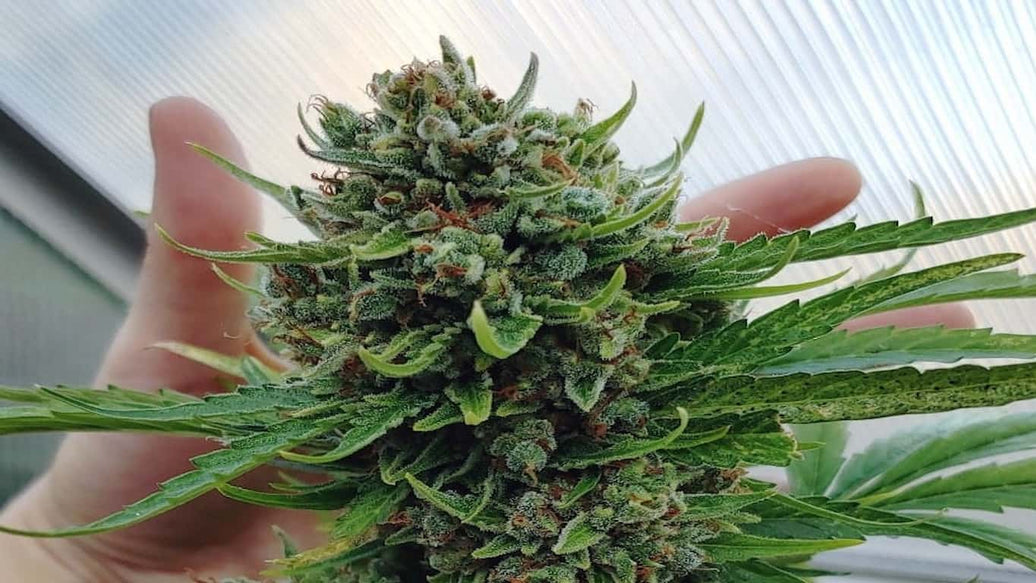

Trichome maturity assessment

- Use a 30× - 60× magnifying loupe to inspect trichomes on calyxes and sugar leaves.

- Harvest when most trichomes are milky white with a few amber heads - this balance maximizes THC levels without excessive degradation.

Optimal environmental conditions

- Maintain a clean, well-ventilated workspace free of dust and contaminants.

- Sterilize all cannabis harvesting tools (pruners, trays, shears) with 70% isopropyl alcohol before each session to prevent mold and microbial growth.

Tools checklist

- Bypass pruning shears/scissors: Sharp, flush cuts reduce plant trauma - see our “1 lb Ruksak Bags” product page for compatible trimming kits.

- Handheld loupe/microscope: Refer to our “Cannabis Harvest Chart” blog for detailed magnification guides.

- Nitrile gloves & trays: Protect bud integrity and keep work surfaces sanitary.

Preparation reduces errors and ensures that all cannabis harvesting equipment functions optimally from the first cut to final cure.

Manual harvesting tools and techniques

Manual methods remain indispensable for small grows and craft batches, where precision and visual quality checks are paramount.

Precision cutting tools

Bypass pruners vs. fine-tip trimmers:

- Bypass pruners: Ideal for thick stems (up to ¾″ diameter), delivering clean shears that heal rapidly.

- Fine-tip trimmers: Perfect for delicate sugar leaves and flower separation, minimizing terpene loss.

Ergonomic considerations: Look for cushioned grips and contoured handles to reduce hand fatigue during extended trimming sessions.

Trimming methods

- Wet trimming: Removing fan leaves immediately after harvest speeds drying and reduces mold risk. This method pairs well with handheld scissors and wet trimmers for a faster workflow.

- Dry trimming: Hanging whole branches before trimming preserves trichome-rich sugar leaves, enhancing cannabinoid retention. Tools like handheld trimmers and curved trimming scissors excel in this slower, detail-oriented process.

Step-by-step hand-trim procedure

- Hang entire plant or cut branches in a dark, 50% humidity room at 60–70°F.

- Once stems snap (usually 7–14 days), remove buds from branches.

- Using fine-tip trimming scissors, gently shear away sugar leaves, rotating buds to expose hidden areas.

- Collect trimmed leaves for kief extraction or secondary extraction processes.

Postharvest drying and curing essentials

- Hanging systems & drying racks: Stainless steel rods or mesh racks enable even air circulation.

- Curing jars & ATMOSIScience Humidi-Cure®: After drying, transfer buds to airtight glass jars. Insert Humidi-Cure® humidity packs to maintain 62% RH, preventing overdrying and preserving flavor.

Mechanical harvesting equipment

For medium to large operations, automated cannabis harvesting equipment accelerates throughput while maintaining consistent quality.

Buckers and bud removers

Function & yield benefits: Buckers strip buds from branches without severing calyxes; ideal for pre-trim removal.

Recommended models:

- Mobius M108S Bucking Machine: Processes up to 40 lbs/hr of fresh bud with minimal bud damage.

- Outco Buckmaster™ Systems: Robust stainless steel construction for commercial durability.

Automated trimmers

Automated trimmers reduce manual labor and standardize trim quality, critical for large-scale producers.

Wet trimmers:

- Process freshly harvested, un-dried material.

- Adjustable blade speed (up to 1200 RPM) and screen sizes (3 mm–8 mm) cater to diverse bud densities.

Dry trimmers:

- Handle cured buds for a gentler trim, preserving trichomes.

- Integrated vacuum collection systems minimize bud loss.

Key features to compare

|

Feature |

Wet trimmer |

Dry trimmer |

|

Throughput (lbs/hr) |

50–150 fresh buds |

30–80 cured buds |

|

Blade speed |

800–1200 RPM |

400–800 RPM |

|

Screen options |

Multiple screen diameters |

Selective mesh for trichome retention |

|

Vacuum integration |

Optional |

Standard |

High-volume cultivators should consider ROI: machines often pay for themselves within two harvest cycles through labor savings and reduced bud loss.

Sorting and conveying systems

- Grade separation: Conveyors with adjustable dividers sort bud sizes for tiered trimming.

- Quality control integration: Inline optical sorters detect stems and leaves, rejecting off-spec material prior to trimming.

Large-scale mechanical harvesters

Field-scale equipment bridges the gap for hemp and outdoor cannabis cultivations.

- Stripper headers & threshers: Mounted on tractors, these devices strip flowers and seed heads en masse.

- Wood chipper adaptations: Modified blades gently agitate branches, separating buds without shredding trichomes.

- Labor & cost considerations: While capital-intensive, mechanical harvesters drastically cut field labor and accelerate postharvest timelines.

Postharvest best practices and storage

Ensuring the integrity of harvested cannabis extends beyond initial trimming. Proper postharvest care and storage preserve cannabinoids and terpenes, maximizing product value.

Equipment cleaning and sterilization

- Sanitize all cannabis harvesting tools and machines between batches to prevent cross-contamination.

- Disassemble trimmers and conveyor belts weekly for deep cleaning using food-grade detergents.

Drying environment control

- Maintain 50% RH at 60–70°F; rapid drying shrinks trichomes, while slow drying risks mold.

- Use dehumidifiers and HEPA-filtered fans to stabilize airflow and air quality.

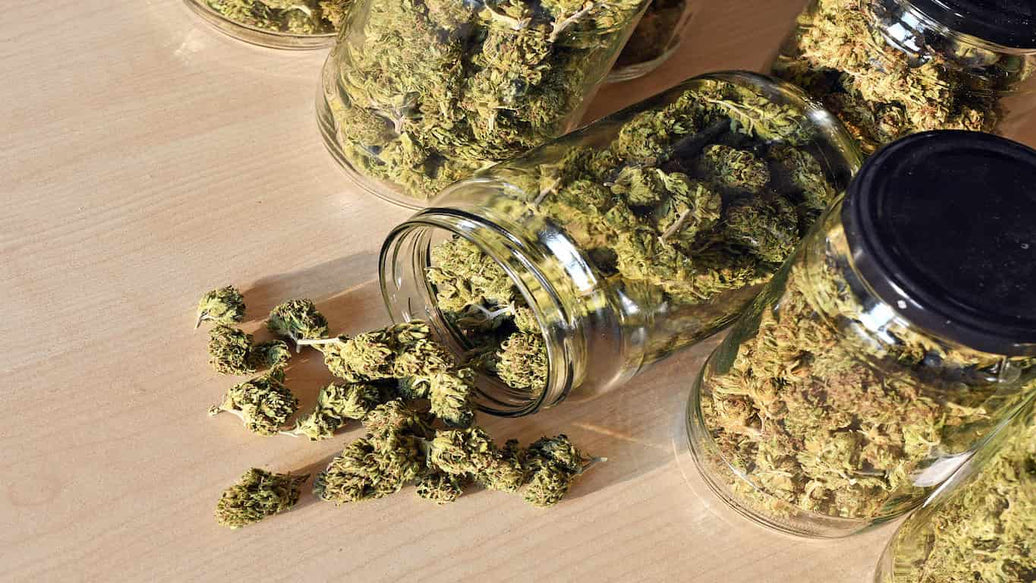

Curing in airtight containers

- Transfer dry buds into glass jars filled no more than ¾ full.

- Incorporate ATMOSIScience Humidi-Cure® packs to maintain an ideal 58–63% relative humidity.

- “Burp” jars daily for two weeks, monitoring moisture and aroma to avoid condensation.

Discover also our 1 lb ruksak Bags: Vacuum-seal pouches for kief and trim storage.

Conclusion

Selecting the proper blend of cannabis harvesting tools and cannabis harvesting equipment is critical to achieving maximum potency, yield, and operational efficiency. Small grows benefit from precision manual shears and hand-trimming methods, while larger operations see significant ROI through automated buckers, trimmers, and conveying systems. Pair these tools with rigorous timing, sterile postharvest procedures, and ATMOSIScience storage solutions to elevate product consistency and market value.

Equip your grow with ATMOSIScience’s full suite of harvest and storage products - unlock the true potential of every harvest.

For advanced storage strategies, see our blog “Optimal weed storage” featuring detailed jar lining techniques and humidity pack guides.