Relative humidity (RH) is a critical environmental factor that affects various industries, including electronics manufacturing, pharmaceutical production, and food processing. Proper relative humidity control ensures that environments are conducive to product quality, safety, and efficiency. In this blog, we will explore the importance of relative humidity control, discuss its application in different fields, outline the components of a relative humidity control system, and provide insights into effective relative humidity control methods.

As industries strive to optimize their processes, understanding the role of relative humidity becomes increasingly important. Relative humidity affects not only the quality of products but also the health and comfort of occupants in these environments. By maintaining optimal relative humidity levels, industries can reduce waste, improve product reliability, and enhance overall operational efficiency.

How can the term "relative humidity" be explained?

Relative humidity is a measure of the amount of water vapor present in the air compared to its maximum capacity at a given temperature. It is represented as a percentage, indicating how close the air is to saturation. This concept is crucial in understanding weather patterns and environmental conditions.

Warm air holds more moisture than cold air, so RH fluctuates with temperature changes. For example, at 100% RH, the air is saturated, leading to condensation (dew, fog) when cooled further.

Measuring relative humidity

Accurate RH measurement is critical for industrial, agricultural, and environmental applications. Common methods include:

- Thermo-hygrometer: Measure changes in capacitance as moisture alters dielectric properties between two plates (e.g., polymer-based sensors).

- Psychrometer: Use two thermometers (wet-bulb and dry-bulb) to calculate RH via evaporation rates.

- Dew point hygrometer: Cool a surface until condensation forms; the dew point temperature determines RH.

Thermo-hygrometer from ATMOSIScience

Psychrometer measures relative humidity

Role of relative humidity

Relative humidity impacts health, safety, and operational efficiency across industries:

- Human comfort: High RH can make the air feel warmer, leading to discomfort and health issues like heat exhaustion or heat stroke. Conversely, low RH can cause dry skin, irritate the eyes and throat, and exacerbate respiratory conditions.

- Industrial processes: In industrial environments, RH affects the integrity of stored materials and the reliability of machinery. High RH can lead to the growth of mold and mildew, while low RH can cause materials to dry out and lose their effectiveness.

Relative humidity control across industries

Relative humidity control is vital in various sectors, each with its unique requirements:

Pharmaceutical industry

Relative humidity control in pharmacy is paramount for maintaining the quality and efficacy of drugs. High humidity can alter the composition and effectiveness of pharmaceuticals by destabilizing or degrading ingredients, and it contributes to the growth of mold and mildew. For example, the optimal humidity level for powder and compound pills and gelatin capsules should remain no higher than 25% RH to prevent moisture-related issues.

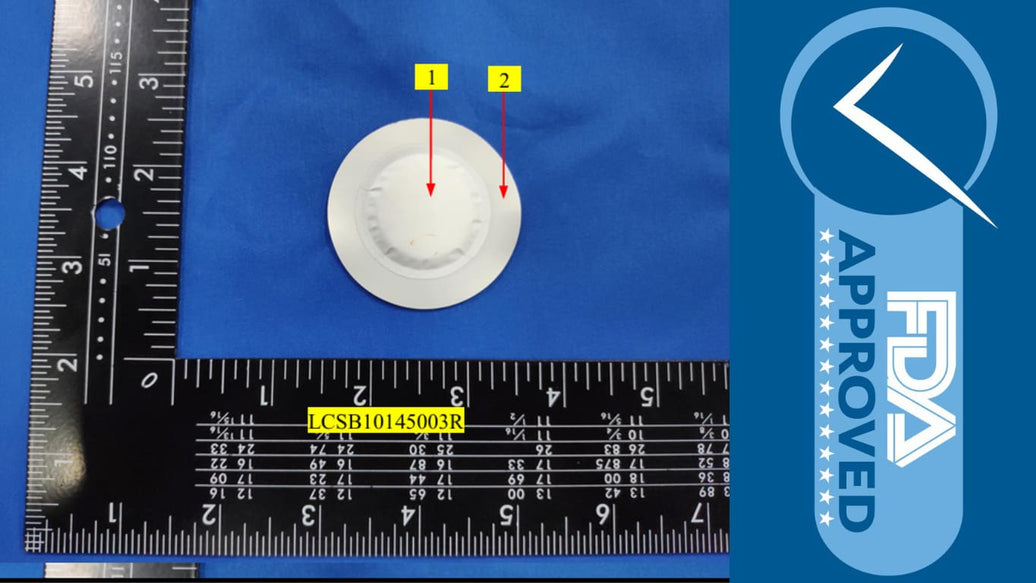

Regulatory bodies, such as the FDA and WHO, mandate strict humidity levels to prevent chemical degradation and microbial contamination. Key considerations for relative humidity control in pharmacy include:

- Storage conditions: Maintaining RH levels between 35%-65% to prevent moisture-sensitive drugs from losing potency.

- Manufacturing facilities: Implementing dehumidifiers and air conditioning to keep production areas within acceptable humidity ranges.

- Packaging and transport: Using moisture-resistant packaging and controlled transport conditions to avoid exposure to excessive humidity.

Food storage and processing

Maintaining optimal RH levels in food storage and processing ensures product freshness and prevents microbial growth. Dry goods require low humidity to prevent spoilage, while certain perishable items need controlled moisture levels to retain quality. Relative humidity control methods such as climate-controlled storage and dehumidifiers are widely used in this industry.

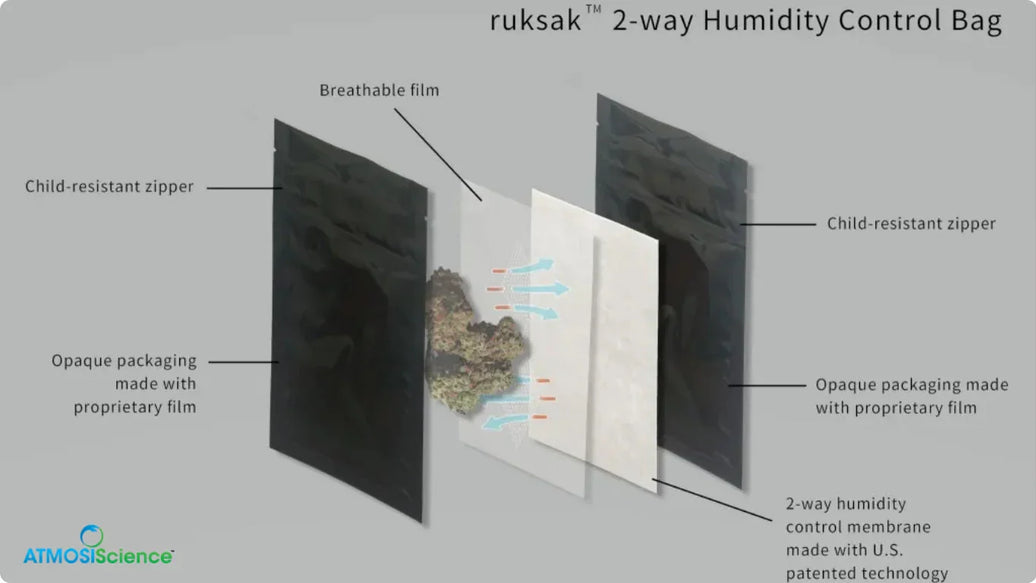

ruksak packs or other desiccants can absorb moisture in storage containers or device casings. These materials are effective for controlling humidity in small, enclosed spaces where electronic components are stored or transported.

In the food processing industry, excessive humidity can lead to mold growth, spoilage, and contamination, compromising food safety and reducing shelf life. Optimal RH levels typically range from 45% to 55% to maintain product quality and prevent moisture-induced damage.

Electronics manufacturing

Humidity control is crucial in electronics manufacturing to prevent electrostatic discharge (ESD) and moisture-related damage to sensitive components. Maintaining RH levels between 40%-60% reduces static buildup and protects circuit boards from corrosion and short-circuiting. Relative humidity control systems integrated with HVAC and dehumidifiers help maintain stability in production facilities.

Textile manufacturing

In the textile industry, controlling relative humidity is essential to maintaining fabric quality and preventing defects in production. High humidity levels help keep textile fibers flexible and reduce static electricity, which can interfere with machinery and product consistency. Maintaining RH levels between 50%-70% prevents excessive fiber breakage and ensures smooth weaving and dyeing processes.

Automotive manufacturing

Relative humidity control plays a significant role in automotive manufacturing, where precise environmental conditions are required for assembling and painting vehicle components. High humidity can lead to condensation, affecting metal surfaces and leading to corrosion. On the other hand, low humidity increases static electricity, which can interfere with electronic systems and component assembly. Keeping RH levels between 40%-60% in assembly lines and painting facilities ensures high-quality production and durability.

Relative humidity control system solutions

A relative humidity control system is designed to maintain optimal humidity levels in indoor environments. These systems work by either adding moisture to the air when it is too dry or removing moisture when the air is too humid. They can be standalone units or integrated into a building’s HVAC system.

To ensure consistent environmental conditions, businesses invest in relative humidity control systems designed for specific needs. These systems include:

- Centralized climate control: Integrates humidity management with heating and cooling systems for large-scale applications.

- Localized dehumidification units: Used in storage rooms, laboratories, and cleanrooms for precise moisture control.

- Zoned humidity control: Allows different areas within a facility to have customized humidity settings for specific operations.

Effective relative humidity control methods involve using a combination of humidifiers, dehumidifiers, and temperature control systems. Temperature control can also influence relative humidity by changing the air’s capacity to hold moisture.

- Humidification and dehumidification: Humidifiers work by releasing water vapor or steam into the air, while dehumidifiers cool the air to condense moisture, which is then collected and removed. The choice between these methods depends on the specific needs of the environment.

- Temperature control: Controlling temperature can be an effective way to manage relative humidity, as warm air can hold more moisture than cold air. However, this method is not always energy-efficient, especially in large spaces.

As we navigate the complexities of modern industry, relative humidity control emerges as a vital component of operational success. By understanding and managing relative humidity effectively, businesses can unlock significant improvements in product quality, worker safety, and environmental sustainability. Whether in pharmaceuticals, food processing, or other sectors, precise control of relative humidity is no longer a luxury but a necessity.

In this era of rapid technological advancement and increasing environmental awareness, companies that prioritize relative humidity management will be better positioned to adapt to changing market demands and regulatory landscapes. By embracing innovative solutions and best practices in humidity control, industries can not only enhance their bottom line but also contribute to a more sustainable future.

Ready to transform your operations with effective relative humidity control? Join the ATMOSIScience community today and discover how our comprehensive solutions can help you optimize your facility’s efficiency, productivity, and sustainability. From detailed site assessments to tailored humidity management strategies, we empower businesses to achieve their full potential in a rapidly evolving world.

Take the first step towards a more efficient, compliant, and sustainable future. Contact ATMOSIScience to schedule a consultation and explore how our expertise can help you harness the power of relative humidity control to drive success across your organization.