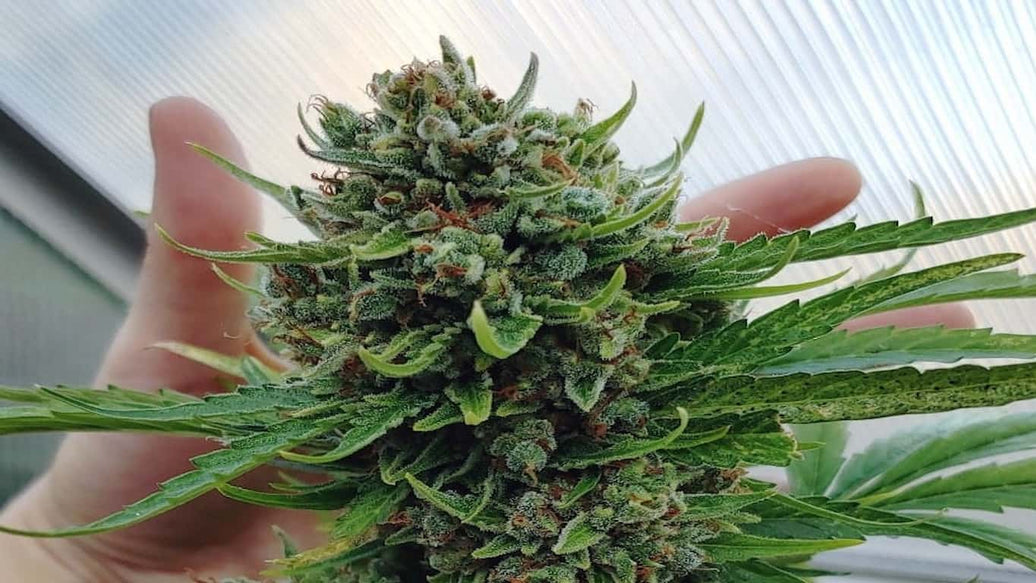

Cannabis extraction stands at the forefront of the cannabis industry, enabling the transformation of raw plant material into highly concentrated and bioavailable forms known as cannabis extracts and cannabis oil extract. These potent products serve diverse applications across medical, therapeutic, and recreational segments.

The art and science of cannabis extraction have matured significantly, evolving from primitive solvent soaking into a sophisticated landscape of solvent and solventless techniques, precision temperature and pressure control, and rigorous quality assurance. This evolution shapes product potency, flavor, safety, and ultimately, consumer experience.

Equipping yourself with comprehensive knowledge about cannabis extraction aids both producers and consumers in navigating this complex terrain to ensure efficacy and safety.

The chemistry behind cannabis extraction: Cannabinoids and decarboxylation

Cannabis synthesizes cannabinoids mainly in acidic forms: tetrahydrocannabinolic acid (THCA) and cannabidiolic acid (CBDA). To unleash therapeutic and psychoactive properties, these acidic precursors require decarboxylation —conversion through controlled heat to active THC and CBD.

Effective decarboxylation typically occurs within 220-240°F over 30 to 40 minutes. This step is critical, enabling cannabinoids to interact with the human endocannabinoid system effectively.

Simultaneously, practitioners must preserve valuable terpenes—the aromatic compounds responsible for flavor and synergistic effects. Optimizing temperature to balance activation and preservation is essential in producing high-quality cannabis oil extract products.

Discover more: What Exactly Are Cannabis Terpenes?

Solvent-based extraction Techniques: Science driving quality and efficiency

Supercritical CO₂ Extraction: The industry gold standard

Operating CO₂ at temperatures and pressures above its critical point, this supercritical fluid acts as a selective solvent for cannabinoids and terpenes. Its tunability, non-toxic nature, and environmental sustainability make it the preferred industrial method.

Equipment costs are high, but the resulting cannabis extract boasts purity, potency, and full-spectrum chemical profiles. Extraction parameters like pressure (up to 300 bar) and temperature (40-70°C) are optimized for targeted compound recovery.

Yields approach 40% cannabinoid purity in well-engineered systems, with exceptional terpene preservation compared to alcohol or hydrocarbon methods.

Ethanol extraction: Versatile and scalable

Cold ethanol extraction leverages food-grade alcohol’s solvent power to capture cannabinoids and terpenes effectively. By freezing plant material and ethanol, this method minimizes chlorophyll co-extraction, producing cleaner cannabis extracts suitable for tinctures, vape oils, and edibles.

Ethanol extraction recovery rates exceed 80% CBD in optimal conditions. It is cost-effective and safer for operators than hydrocarbons but requires solvent removal via vacuum evaporation.

Hydrocarbon extraction: Maximizing terpene and cannabinoid retention

Butane and propane extraction remain popular for manufacturing flavor and terpene-rich concentrates like live resin, shatter, wax, and crumble. Low temperatures and closed-loop systems preserve compounds but demand rigorous safety measures due to solvent volatility.

Efficient purging reduces residual solvents to safe levels, yielding cannabis extracts with exceptional potency and flavor fidelity—cornerstones of premium concentrate markets.

Solventless extraction techniques: Purity through mechanics

Rosin pressing: Preserving potency without solvents

By applying controlled heat and pressure, rosin pressing mechanically extracts resin from flower or hash. This yields solvent-free cannabis extracts with robust cannabinoid and terpene content, attractive for health-conscious consumers.

Typical yields range from 15% to 30%, with live rosin—produced from fresh-frozen material—maintaining even greater terpene integrity and premium product status.

Ice water extraction and dry sift

Ice water hash employs agitation in icy water to separate trichomes, while dry sift uses micron sieving to isolate resin glands. Both methods produce solventless extracts prized for purity and retaining the plant's natural profile.

These methods form the base for rosin pressing and high-terpene concentrates, but are labor-intensive and suited for smaller batches.

Advanced and emerging cannabis extraction technologies

Ultrasound-assisted extraction uses acoustic energy to disrupt plant cells and increase yield in shorter times, improving throughput and extraction efficiency.

Deep eutectic solvents (DES) offer biodegradable, low-toxicity alternatives with selective extraction profiles, heralding a shift to sustainable and eco-friendly cannabis oil extract production.

Optimizing cannabinoid profiles and terpene preservation for maximum therapeutic effect

Full-spectrum cannabis extracts encompass a broad array of cannabinoids and terpenes, leveraging the entourage effect. This synergy enhances efficacy over isolated cannabinoids like pure CBD.

Extraction and decarboxylation processes tend to reduce terpene content, sometimes by 90%, necessitating careful method selection and temperature control to conserve these volatile compounds.

Using fresh-frozen material for live resin or live rosin production retains substantially more terpenes, delivering superior aromatic and therapeutic experiences.

Industry-standard quality control for cannabis extracts

Ensuring consumer safety and product consistency starts with comprehensive analytical testing:

- HPLC quantifies major and minor cannabinoids with high resolution.

- GC-MS profiles terpene content and detects trace level solvents.

- Microbial testing for pathogens and mycotoxins is critical.

- Residual solvent analysis confirms the absence of harmful chemical traces.

Compliance with local and federal regulations (GMP, ISO 17025) involves documented standard operating procedures and batch traceability.

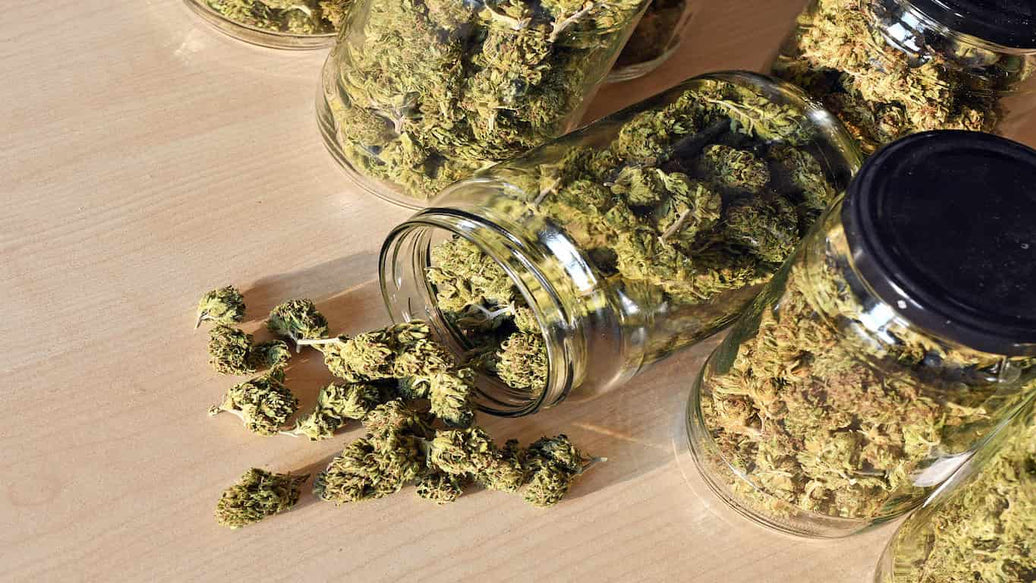

Best practices for storing and preserving cannabis extracts

Storage conditions drastically impact cannabis extract shelf-life:

- Maintain temperature between 59 and 68°F to minimize cannabinoid degradation.

- Relative humidity between 40-65% balances moisture retention without promoting mold.

- Opaque, airtight glass containers protect against light and oxygen damage.

Improper storage can cause over 80% THC loss within two months. ATMOSIScience addresses these challenges with advanced cannabis storage solutions featuring 2-way humidity control, preserving product integrity for extended periods.

Innovative applications: Increasing bioavailability and expanding cannabinoid horizons

Nano-emulsion technology transforms cannabis oil extract by reducing cannabinoid droplet size, vastly improving bioavailability from 6% to 40-80%. This allows for faster, more efficient dosing and enhanced therapeutic outcomes.

Advanced extraction also focuses on minor cannabinoids like CBG, CBC, and CBN, untouched by many products but offering unique health benefits. Extraction refinement unlocks this potential for next-generation cannabis extracts.

Sustainable extraction and waste management

Cannabis extraction increasingly emphasizes sustainability:

- Adoption of green solvents like DES reduces environmental impact.

- Energy-efficient supercritical CO₂ systems recycle solvents.

- Post-extraction biomass repurposing into biofuels, construction materials, and animal feed supports zero-waste goals.

Sustainable cannabis extraction aligns industry growth with environmental responsibility.

Conclusion

As technology and regulation advance, cannabis extraction science stands as a dynamic, evolving field. Producers confident in their methods, backed by stringent quality control and supported by expert storage solutions like those offered by ATMOSIScience, will deliver superior cannabis oil extract products that meet patient and consumer expectations.

By mastering the art and science of cannabis extraction, the industry can ensure products remain potent, safe, and therapeutically effective—now and into the future.