Croptober signals the climax of the outdoor cannabis growing season, when changing photoperiod and cooler nights push buds into their final stages of maturity. For cultivators, it’s a race against time: harvest too early, and the cannabinoid profile remains suboptimal; harvest too late, and bud quality can suffer from mold or over-ripeness. Beyond timing, post-harvest handling is equally critical. This blog will dissect each phase of Croptober harvest, detail the science behind proper moisture management, and provide a step-by-step guide to using ATMOSIScience’s professional humidity solutions to lock in potency, flavor, and shelf life.

The science of croptober maturity

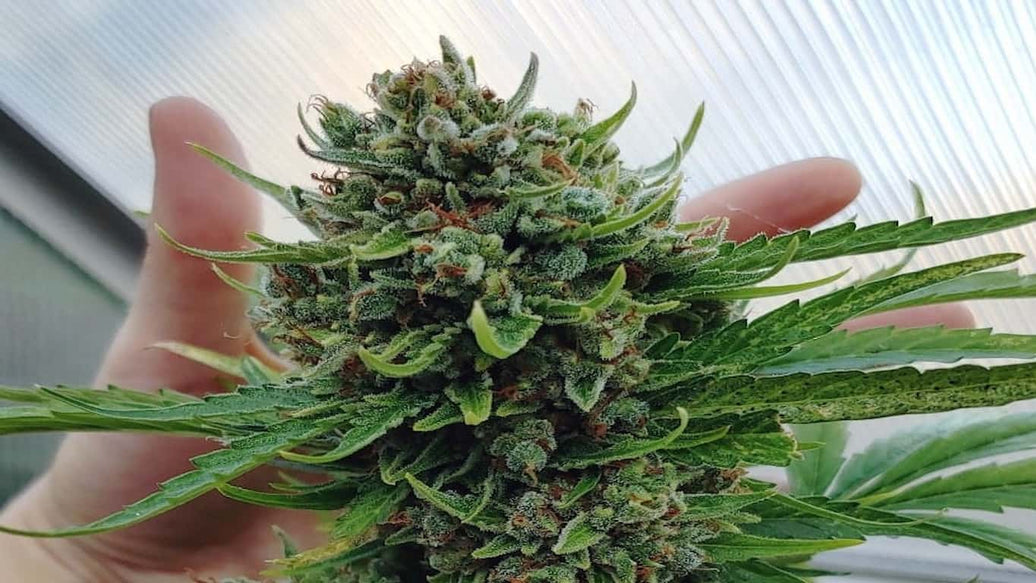

During Croptober, declining day length and cooler nighttime temperatures trigger biochemical pathways in Cannabis sativa that enhance trichome development and accelerate cannabinoid synthesis. As daylight dips below 12 hours, the plant diverts energy from vegetative growth to resin production—boosting the concentration of THC, CBD, and terpenes that define aroma and effect.

However, Croptober also brings unpredictable swings in ambient humidity and temperature. Morning dew, sudden rain events, and chilly nights can raise relative humidity above 65%, creating a breeding ground for Botrytis cinerea (bud rot) and other molds. Conversely, unseasonably dry afternoons can drive RH below 40%, accelerating desiccation and leading to brittle buds that crack open, releasing volatile terpenes to the atmosphere.

Cultivators often misjudge local microclimates, harvesting based solely on calendar dates or trichome color without accounting for real-time humidity control. For premium-quality buds, monitoring both the trichome ripeness (using a 30–60× loupe) and ambient RH/temperature during the final week before chop is essential. Tools such as digital hygrometers provide continuous feedback, ensuring harvest decisions align with optimal moisture conditions rather than arbitrary schedules.

Understanding the "Croptober trap”

The "Croptober trap” encompasses three main hazards:

- Overdrying, which accelerates terpene volatilization, robbing buds of their signature aromas.

- Mold proliferation, which thrives when buds remain above 60% RH during or after drying.

- Inconsistent curing, leading to uneven moisture distribution that causes bud breakage and flavor inconsistencies.

Academic studies show that terpene profiles can decline by up to 30% when RH falls below 40% during the initial drying phase. Conversely, maintaining RH above 60% for more than 48 hours post-harvest raises mold risk by 2.7×. Traditional barn-style hang-drying—uncontrolled and subject to ambient conditions—often swings between these extremes, trapping growers in a cycle of mold outbreaks followed by compensatory overdrying.

Controlled-atmosphere drying, using sealed chambers with adjustable RH, can reduce drying time by 2.5× while keeping mold at bay. However, these systems are cost-prohibitive for many small-scale operations. The more accessible solution is precise, jar-based curing with humidity stabilization—a method proven to maintain ideal moisture content (10–12%) without specialized infrastructure.

Why humidity control is non-negotiable

Water content in cured cannabis is not synonymous with microbial susceptibility; water activity (aw)—the fraction of unbound water available for microbial metabolism—is the decisive factor. Buds must reach a moisture content low enough to inhibit mold yet high enough to preserve volatile oils. Optimal drying-room parameters are 55–65°F and 50–60% RH, a window supported by multiple peer-reviewed analyses. Within this range, enzymatic breakdown slows without triggering terpene evaporation.

At 55°F/55% RH, microbial growth is curtailed, and terpene retention rates exceed 85% compared to uncontrolled environments. Deviations as small as 5% RH can lead to measurable losses: dropping RH to 45% causes a 22% loss in pinene and limonene within 24 hours, while raising RH to 65% for the same period increases mold spore germination probability by 40%. Thus, consistent ambient control throughout drying and curing is essential for preserving cannabinoid profiles and aromatic compounds.

Discover more: The Way You’re Storing Weed Might Be Causing Mold

Pro-trusted humidity control fix: ATMOSIScience solutions

ATMOSIScience offers a suite of professional humidity control products specifically engineered for cannabis post-harvest. The cornerstone is the 62% RH humidity pack—composed of saturated salt blends within breathable sachets—that regulate jar humidity to within ±2%. Laboratory trials on cured inflorescences demonstrate stable RH maintenance for over four months, with no detectable drop in terpene concentration.

Step-by-step curing protocol using ATMOSIScience:

- Pre-dry stage: Hang harvested buds at 55–60°F, 55% RH for 5–7 days, checking internal RH with a digital hygrometer.

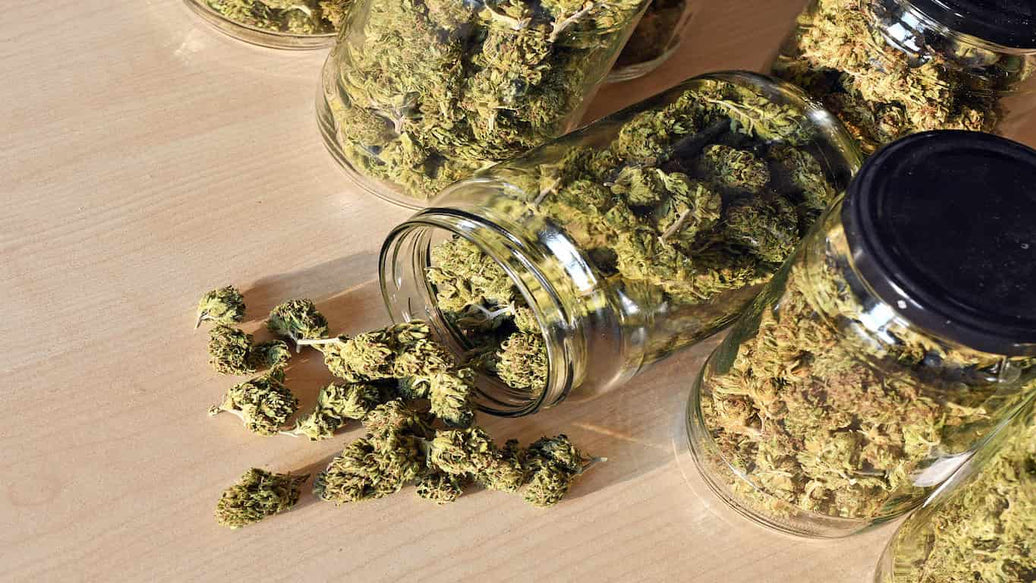

- Jar loading: Transfer buds with 10–12% moisture content to airtight glass jars, filling to 60–70% capacity to allow gas exchange.

- Pack placement: Insert a single 62% RH ATMOSIScience humidity pack per 250 mL jar.

Explore Humidi-Cure® - our superior two-way humidity control pack right now!

- Initial burping: For the first week, open jars twice daily for 10–15 minutes to release residual moisture.

- Stabilization phase: After day 7, burp weekly and replace humidity packs every 60 days.

- Long-term storage: Maintain jars at 60–65°F; packs will keep RH steady, preserving terpene potency for up to six months.

Avoiding the trap: Best practices checklist

- Harvest indicators: Use trichome color (80% cloudy, 20% amber) and pistil retraction rather than calendar date.

- Controlled drying space: Maintain 55–65°F, 50–60% RH with a fan for gentle airflow; monitor with an sensor.

- Cure consistency: Follow the jar-based protocol; avoid overpacking jars to permit gas exchange.

- Humidity pack rotation: Replace 62% RH packs every two months to ensure efficacy.

- Data logging: Record temperature/RH trends in the first two weeks; adjust environmental setpoints to correct deviations.

Conclusion

Croptober harvests reward growers who balance botanical timing with scientific precision. Avoiding “The Croptober Trap” requires mastery of humidity control from hang-dry through long-term curing. ATMOSIScience’s humidity packs offer an affordable, scalable solution to maintain ideal moisture conditions, preserve terpene richness, and secure mold-free yields. Equip your operation with ATMOSIScience products today and transform your Croptober buds into premium-quality flower that delivers consistent potency and unparalleled aroma.